- +86-51258687904

- info@greatabiotechnology.com

- XIZHA VILLAGE,SUZHOU. CHINA

Capillary tube mats for cooling and heating system

About - GREATA manufacturing the capillary tube mats

Greata became the leading global supplier of capillary tube mat products. Today Greata has achieved leadership status in the capillary field. And provides precision engineering products to customers in more than 30 countries in America, Europe and Asia.

Greata is a high-tech enterprise specializing in the development and production of capillary tube mats in China, with a tradition of more than seventeen years.we offer a full range of services for the implementation of a highly energy-efficient water capillary mat heating and cooling system – from system design to its implementation and maintenance, as well as supply and installation of optimally efficient energy sources (heat pumps, gas condensing boilers, etc.), to provide stable, economical and climate-neutral heating and cooling in your premises.

Greata producer with the full range of design, system, materials and finishing and assembly activities and capabilities. Greata’s state-of-the-art manufacturing capability is a fusion of three units over 1 million square feet – the world’s largest installed ability for capillary tube mats. Located in Jiangsu, China, we works hard to improve everything we do. IATF 16949: the comprehensive quality control system registered in 2016 continues to ensure that all products we produce will meet the requirements of customers

Only using German equipment Production Lines

We adopt modern fully automatic equipment and high level precision electronic control system in compliance with strict quality regulations. The advanced equipment, unique technology, experienced production and quality team ensure a very high and 50 years long quality guaranteed of capillary tube mats.

High Quality PPR Raw Material Using only high quality PpR granules which has better rigidity and toughness from Borouge with Rohs test, The PPR material has been tested and proved to be safe with drinking water standard.

Each capillary tube mat is subjected to an strict quality control before it leaves the company and guaranteed the maximum security.Capillary tube mats are precisely prefabricated in accordance with thedimensions required for your project. Freedom of size choice.Short-term delivery times -only 5-10 days

8 full Germany production line to produce the capillary tube mats,17 year production experiences ,and export to 45 countries

Our workshop for capillary tube mats

All Greata capillary tube mats are made in China from high quality polypropylene according to the ISO 9001 and CE standard. Constantly further developed production machines and a unique welding technology for connecting the capillary tube with the mat distributor pipes ensure a very high quality standard and allow a long-term guarantee. Every single product is subjected to an intensive quality control and we will offer a testing report, before it leaves the company.

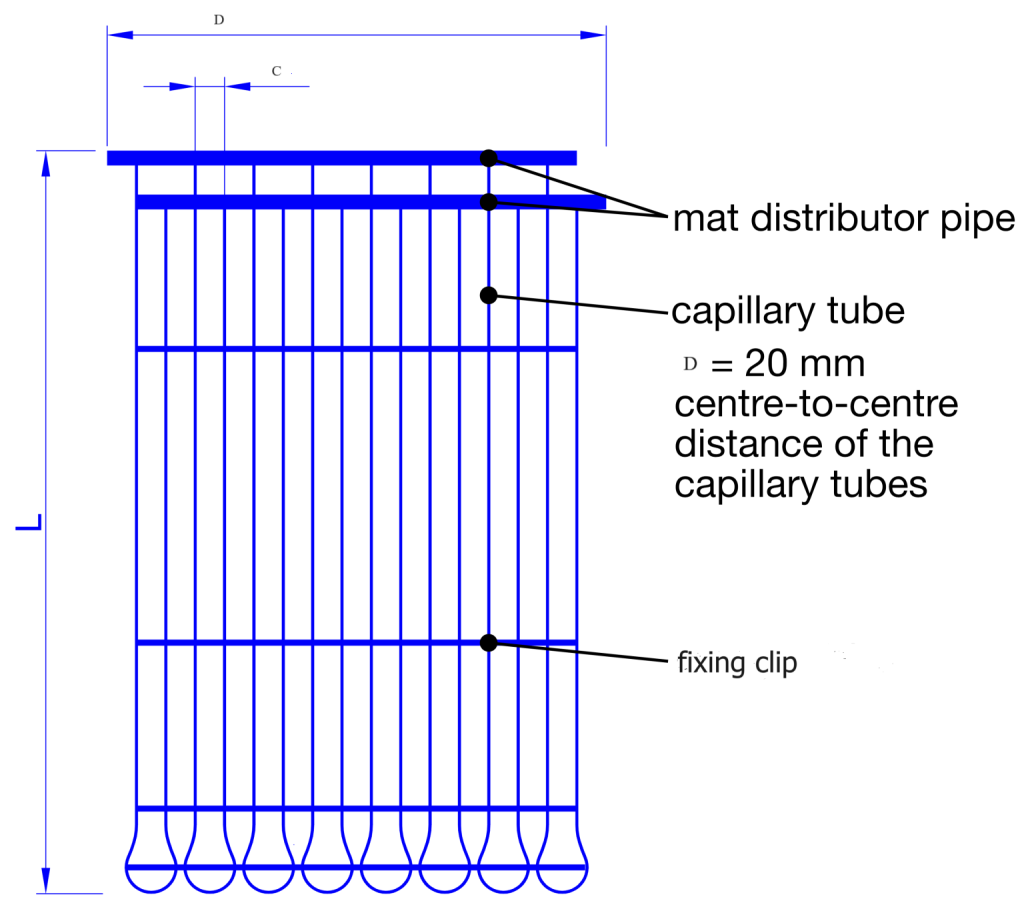

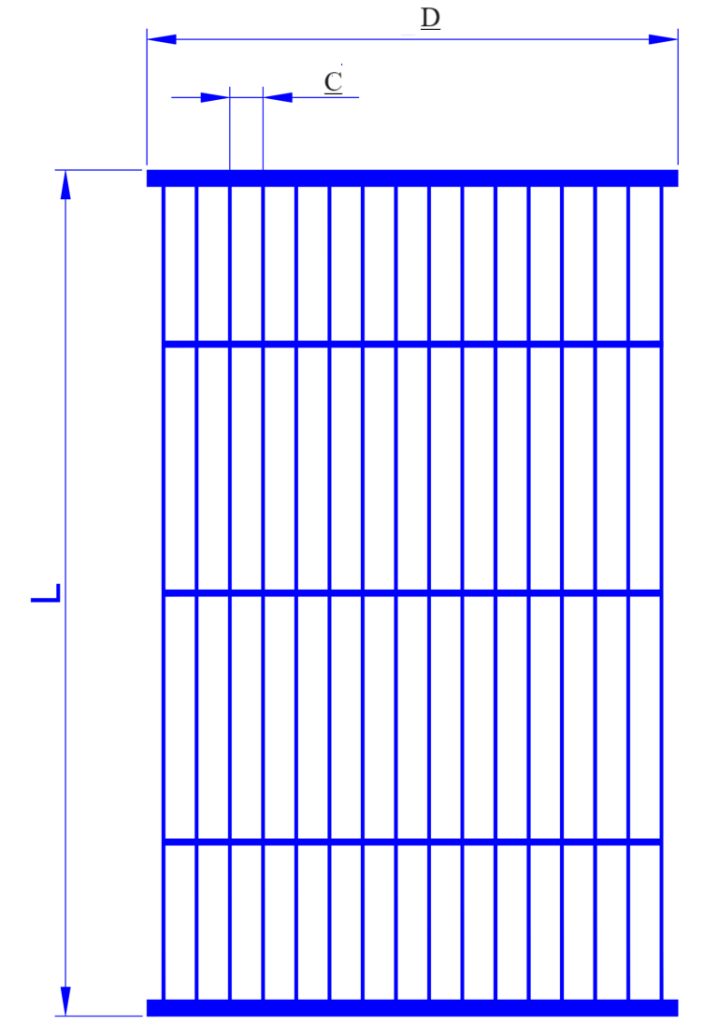

TECHNICAL DATA OF CAPILLARY TUBE MATS

| MATERIAL/COLOUR | Polypropylene (PP-R) recyclable/blue,Green |

| MAT Main PIPE | 20 x 2,0 mm, round |

| CAPILLARY TUBE | 4,3 x 0,8 mm or 3.5* 0.5MM |

| TUBE DISTANCE C | 10 mm,20mm,30mm,40mm |

| LENGTH L | 200 ‐ 12000 mm in 10 mm,20mm steps,,it can be customized according needs. |

| WIDTH C | 100 -1000mm in 20 mm steps,it can be customized according needs. |

| CONNECTION TYPE | with open mat distributor pipes/ |

| SPECATION. WEIGHT | approx. 890 g/m² capillary tube surface |

| SPECATION. VOLUME OF WATER | 0,590 l/m² capillary tube surface |

| SPECATION. TOTAL WEIGHT | approx. 1490 g/m² capillary tube surface |

| PRESSURE STAGE | PN 10 |

MAX. RECOMMENDED OPERATING PRES | 4 bar-6bar |

MAX. ALLOWED HEATING TEMPERATURE Factory test pressure: temperature for cooling: temperature for heating: | 55-60 °C 20 bar + 16-1+ 28 -32° C8 ° C |

15 year warranty

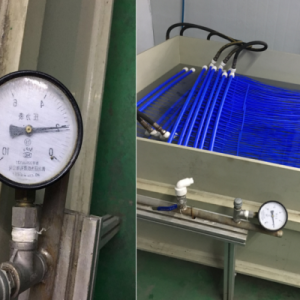

QUALITY CONTROL CAPILLARY TUBE MATS

*100% data monitoring by auto system

*Strict quality control system

*0 defect quality management

*good quality machine

*Experienced welding

*Pressure test at 20 bar

*Testing time more than 21 mins.

*Cover the dust cap after testing

*100% of delivery qualification rate

*100% pressure test for every each capillary tube mat.

*Key points monitoring for capillary tube mats

*Six times random test a day on appearance and welding

*0 defect quality feedback

*Production capillary tube mats process optimization constantly

list

What we do

Manufacturing Capillary tube mat, fitting,tube and pipe,

Capillary tube mat

A capillary tube mat is a type of tubing system that is designed to deliver a specific volume of liquid to a particular location through capillary action.

PPR Tube

PPR tube refers to a type of plastic pipe that is made from polypropylene random copolymer (PPR) material. PPR tubes are commonly used in plumbing systems for hot and cold water supply..

Capillary mat system

The mat consists of a capillary tube mats of small capillary tubes mats that are evenly spaced and can be made from materials such as PPR or plastic.

SECTOR WE SERVER

Capillary mat for heating and cooling system

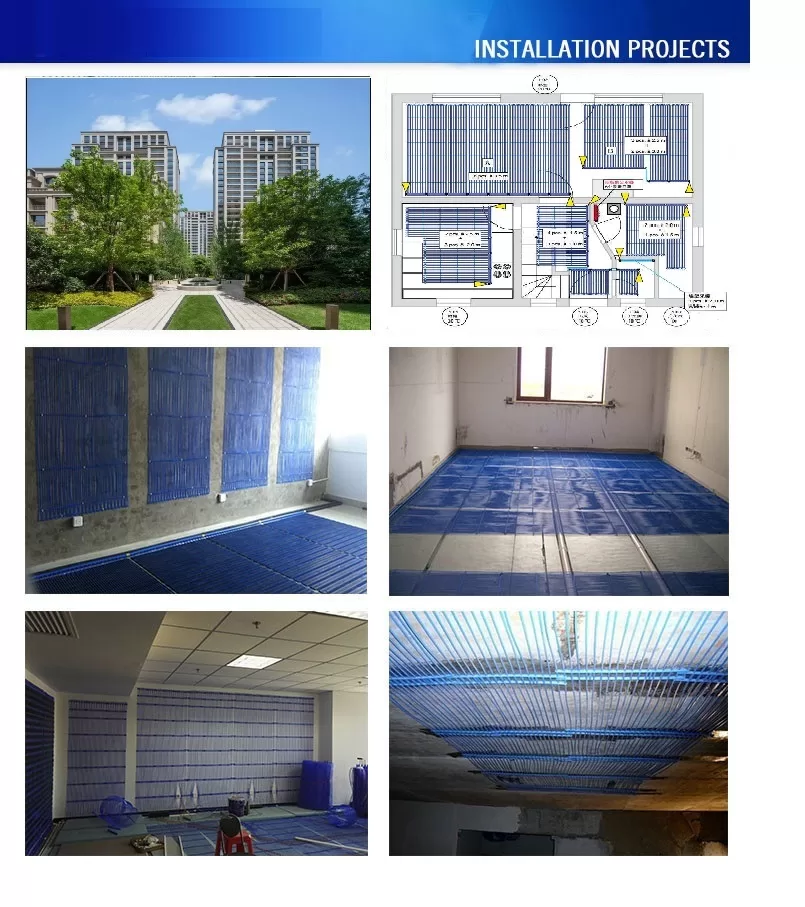

Heating System capillary

Heating System capillary underfloor heating;inside ceiling and wall heatingheating and cooling, if the system is installed in the ceiling or walls.

Cooling System Capillary

The radiant heat exchange technology is a particularly comfortable and energy-efficient solution for room cooling.

There are many installation methods

at the end of the capillary system, including the dry method of integration and the wet method of direct pavement.

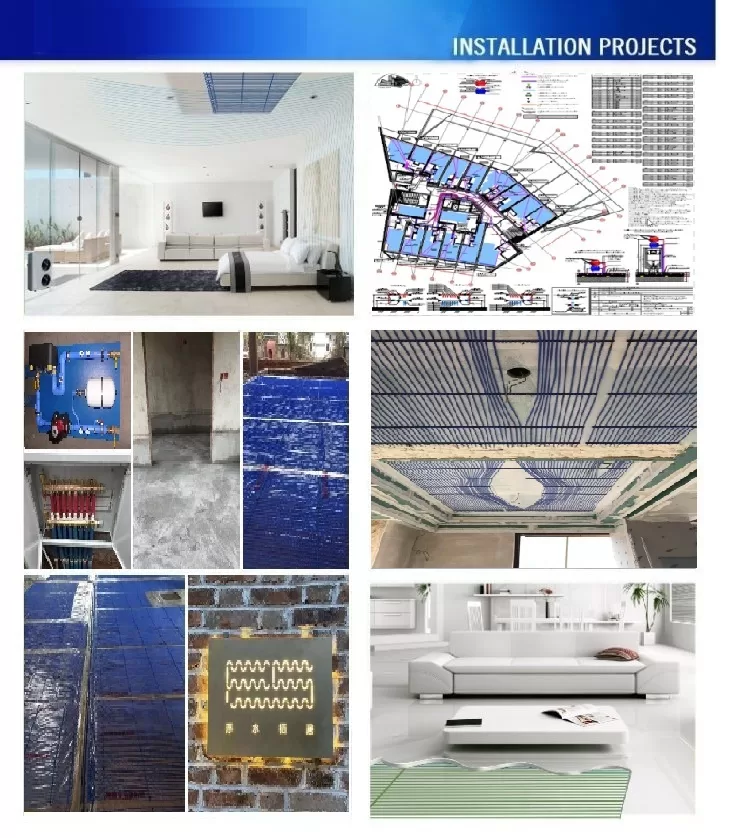

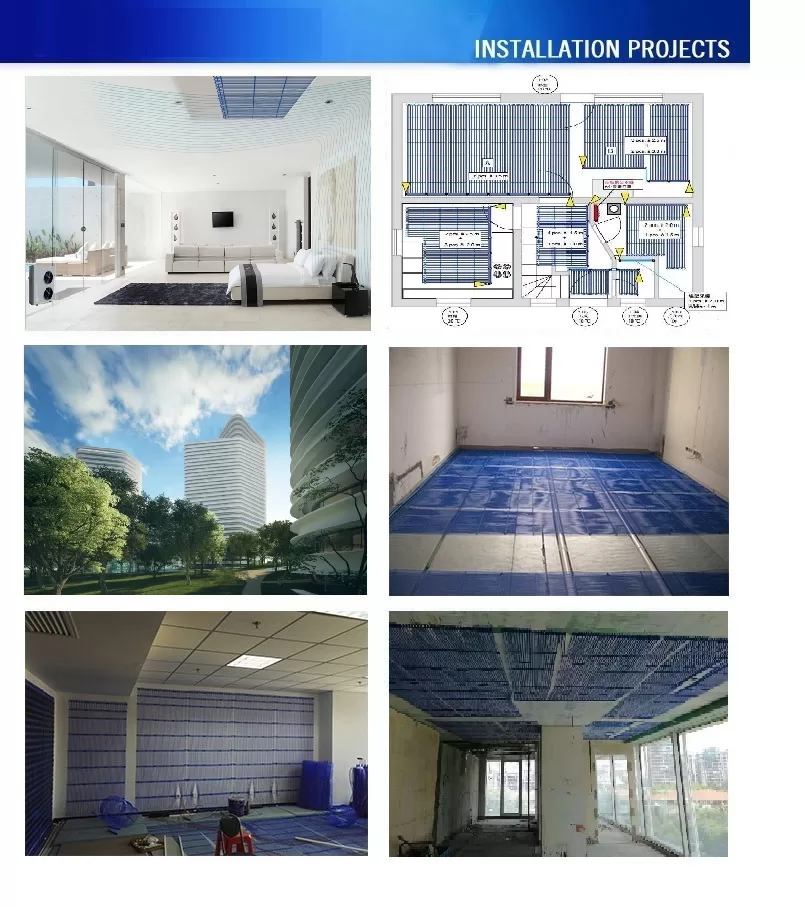

NEW PROJECT WE SUPPLIER

Capillary Tube mat of Examples of realized projects

OBJECT TYPE: HOTEL

Spa Hotel in Lithuania - 100 rooms

Installation of the water capillary mat system in the ceiling under plasterboard.

Heating and cooling for capillary tube mats in one system.

OBJECT TYPE: OFFICE BUILDING

14-floor office building in Germany

Total area: 17200 m2 Installation of the water capillary mat heating and cooling system in the ceiling under plasterboard.

OBJECT TYPE: OFFICE BUILDING

10-floor office building in Germany

Total area: 18 900 m2 Installation of the water capillary mat system in the ceiling under plasterboard.

Greata offers rapid prototyping, capillary tube mat, parts and piping services. With years of production experience, our experts provide the best solution for all your needs of rapid production. We are a leading capillary manufacturer, sample free order! We are one of the leading hemp packers, providing free ordering service!

©2023 Zhangjiagang Greata International. All Rights Reserved.