Ice energy storage with capillary tube mats technology is a form of thermal energy storage that utilizes the phase change of water to store and release energy. This technology is particularly useful for cooling applications in buildings and industrial processes.

Here’s how it works:

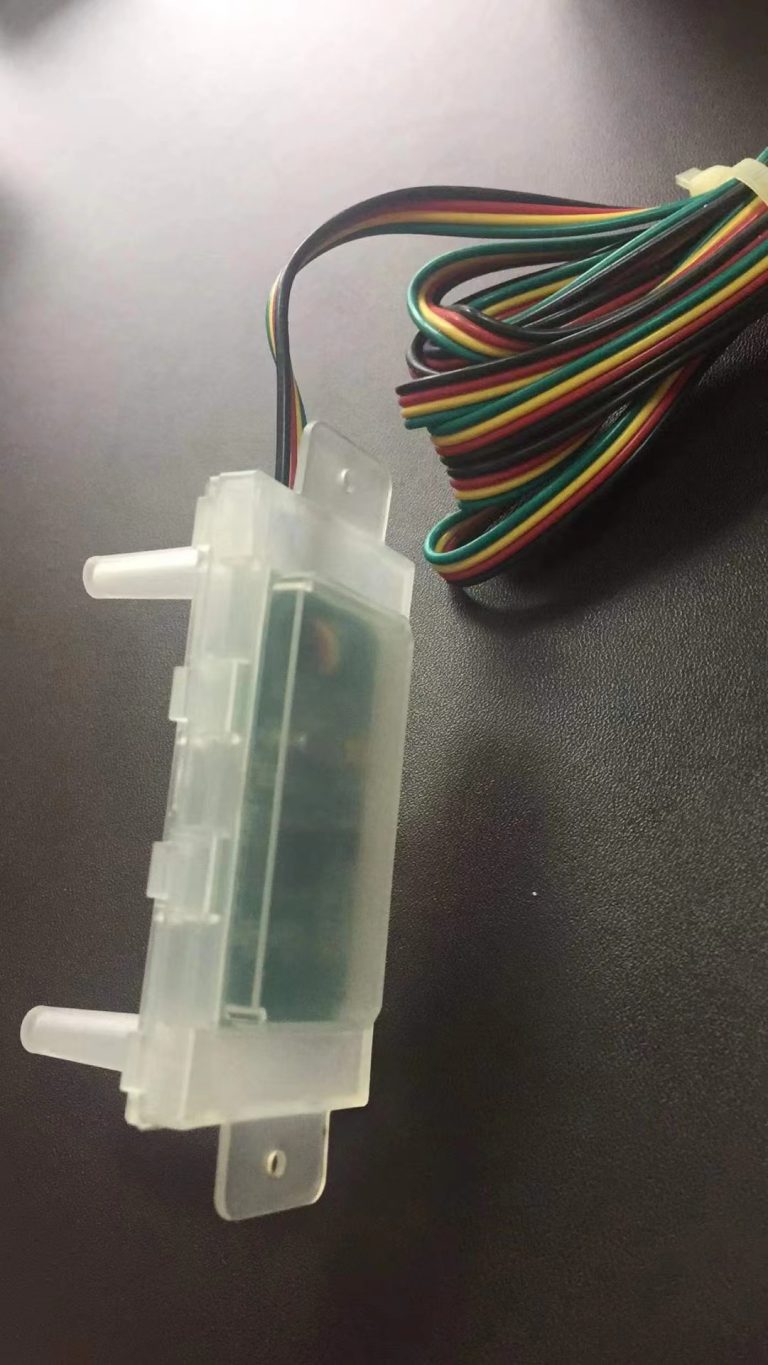

Capillary Tube Mats: These are a network of small-diameter tubes that are installed in the ceiling or walls of a building. These tubes are designed to distribute water evenly across a large surface area. The capillary action of the tubes helps to spread the water uniformly.

Ice Formation: During off-peak hours when energy costs are lower, a chiller system cools water and circulates it through the capillary tube mats. As the water flows through the tubes, it comes into contact with the cooler surrounding environment, causing it to gradually freeze and form a layer of ice on the surface of the mats.

Energy Storage: The ice that forms on the capillary tube mats serves as a thermal energy storage medium. This is because the process of water freezing and melting involves a significant amount of energy exchange, which can be harnessed for cooling purposes later on.

Cooling Cycle: When cooling is needed during peak hours, the circulation of water through the capillary tube mats is reversed. The ice stored in the mats absorbs heat from the surrounding air, effectively cooling the indoor environment. As the ice melts, it absorbs a large amount of heat, providing a sustained cooling effect.

Benefits of Ice Energy Storage with Capillary Tube Mats Technology:

Energy Efficiency: By shifting energy consumption to off-peak hours, this technology helps to reduce overall energy costs and grid demand.

Environmental Impact: It can contribute to a reduction in greenhouse gas emissions, especially if the electricity used during off-peak hours comes from renewable sources.

Space Saving: The installation of capillary tube mats for ice energy storage can be integrated into the building structure, saving space compared to traditional thermal storage systems.

Longer Cooling Periods: Ice energy storage systems can provide cooling for longer durations compared to conventional HVAC systems, especially in regions with high cooling demand.

In summary, ice energy storage with capillary tube mats technology offers an innovative and efficient approach to thermal energy storage, particularly for cooling applications in buildings. Its ability to shift energy consumption, reduce costs, and provide sustainable cooling makes it an attractive option for many industries.

Highly efficient and cost saving cooling for buildings and industrial processes – flexible installation and integration options in existing air conditioning technology

The ICE thermal energy storage, jointly developed by greata, can significantly reduce the energy costs for building air conditioning and industrial processes as a supplementary component for existing cooling technology. Other areas of application are cold networks, emergency cooling systems and thermal energy storage for renewable energy power plants. At the heart of the ice energy storage system are capillary tube mats, which enable a particularly high degree of efficiency and fast reaction behaviour due to the dense arrangement and the large heat transfer surface of the capillary tubes. The installation can be made transportable as a container or underground as a basin below the surface.

Technical Data ICE Energy Storage

Standard ICE container

| Property / Type | Unit | ICE-10´ | ICE-20´ | ICE-40´ |

| Length | mm | 2,991 | 6,058 | 12,192 |

| Width | mm | 2,438 | 2,438 | 2,438 |

| Height | mm | 2,591 | 2,591 | 2,591 |

| Transportation weight | kg | 3,400 | 6,200 | 13,600 |

| Usage weight with filling | kg | 15,400 | 31,700 | 66,800 |

| Total capacity at 10°C initial temperature | kWh | 1,100 | 2,380 | 4,960 |

| Latent capacity | kWh | 965 | 2,100 | 4,355 |

| Discharge performance in 6 hours | kW | 183 | 397 | 827 |

| Discharge performance in 8 hours | kW | 138 | 298 | 620 |

| Discharge performance in 10 hours | kW | 110 | 238 | 496 |

| Refrigeration ton total | RHT | 314 | 679 | 1,414 |

| Refrigeration ton latent | RHT | 275 | 599 | 1,242 |

| Maximum operating pressure | bar | 10 | 10 | 10 |