one way to get heating and cooling system

The Greata water capillary tube mat system can be used heating and cooling system for:

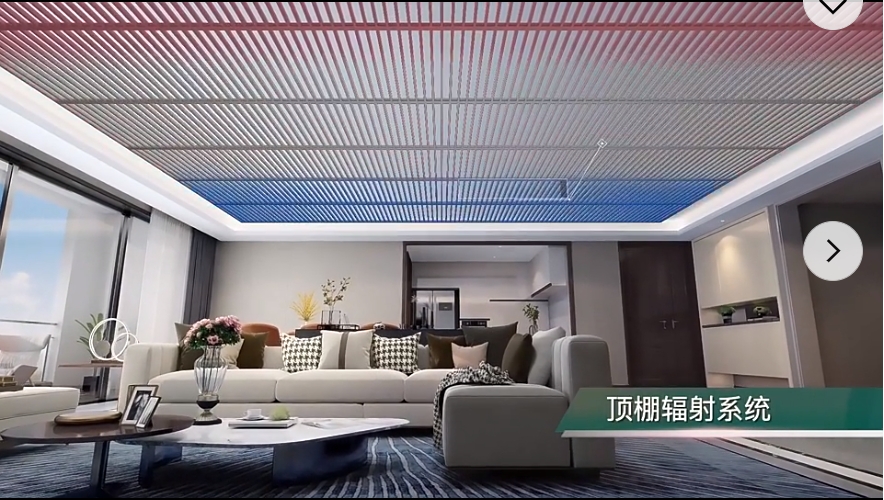

- underfloor or ceiling heating and cooling ;

- heating and cooling, if the system is installed in the ceiling or walls or floor.

Read more about installation options

The ceiling is the largest free space in the room, thus it is recommended to mount the system on the ceiling, supplementing it with installation on the walls or floor, if it is necessary to provide more heating or cooling capacity.

Advantage of the Greata water capillary mat heating and cooling system

Energy-saving:

For heating in winter, the input water temperature is around 28-32℃. Compared with the 45-60℃of common floor heating pipes and 70-80℃of the traditional heating radiator, the capillary tube mat system can save 20-40% energy. For cooling in summer, the input water temperature is around 16-18℃, which is much higher than the 5-7℃of the common air conditioning system, which can help save 60-70% energy.

Saving more Space room:

The thickness of capillary tube mat installation is about 10mm; water filling weight is about 750g/m2.For example: For a 20-floor building with traditional central air conditioning, using capillary tube mat can save 2 floors space, which can form great economical benefits.

Energy Selection:

Capillary tube mat can work together with air source heat pump, sun energy,water source heat pump, ground source heat pump, solar energy,and independent dehumidifying system.

Healthy for breath and Comfortable for body:

Capillary tube mat realizes the heat exchange in a form of radiation. With great heat exchange surface area, capillary tube mat system has the features of no noise, no air flow, no bacterial overgrowth.

Easy Installation :

The diameter of capillary tube mat is only 4.3mm. It can be hidden installed in-wall, ground and ceiling. It doesn’t take up space in the room, has little influence on house decoration and can be easily installed.

Safe and Reliable:

Each piece of capillary tube mat must pass the pressure test of 20 bar before delivery.With high quality, the using life of capillary tube mat is around 50 years. And the whole system can run steadily without maintenance with professional design and installation.

More Application:

Not only Capillary tube mat can be used as the air conditioning terminal product and but also can be used as energy collection terminal.

Low temperature cooling and heating system

sufficient flow temperature of +24-31°C, due to the large area coverage with capillary tube mats

Choice of energy sources

possible to use with various energy sources – central heating,sun energy, gas boiler, pellet boiler, heat pump, etc.

Reduced circulation of dust, viruses and bacteria in the room

significantly reduced circulation of dust, viruses and bacteria together with the air flow, which is especially important to limit the spread of COVID-19

Comfort level

It will not cause dry air and will creates a pleasant indoor climate

Cost savings

excellent cost savings worked with various types of heat pumps

Finishing material savings

requires less dry concrete (Estrich) and other levelling finishing materials for underfloor heating

Extensive installation options

can be installed on the ceiling or walls and in combination with a room cooling system

Read more about the cooling system ›

Reduction of CO2 emissions

According to a report by an independent expert in the field of energy-efficiency, SIA “Ekodoma”, based on the characteristics of the system, the amount of CO2 generated per year by the Hydrokapillare system is 3.25 kg CO2/m2 less than that generated by classic under-floor heating system and 5.9 kg CO2/m2 less than the radiator system.

Energy source

The water capillary tube mat system can be connected to various sources of heat/cold supply.

System efficiency

When calculating the required heating and cooling capacity in a room, the thermal conductivity of the chosen finishing material must be taken into account – the higher it is, the higher the efficiency of the heating / cooling system will be.

In the case of capillary heating, a person feels a temperature of 2-3 degrees higher than the air temperature in the room.

Read more about heating and cooling system planning ›

Comparison of the Greata heating system with other underfloor heating systems

To ensure even heating of the floor surface:

Flow temperature: +35-40°C

Pipes: 17 x 2,0 mm

Distance between pipes: 150 mm

Dry concrete (Estrich) layer: min. 60 mm

Conventional underfloor heating system

Flow temperature: +25-30°C

Capillary tubes: 4.3 x 0.8 mm

Distance between capillaries: 20 mm

Dry concrete (Estrich) layer: min. 20 mm

Greata underfloor heating system

Manifolds for the Greata Hydro capillary system

Supply and return lines of individual zones are connected to manifolds. There are different models available with 2 to 16 outlets.

Important! Connection of max 18 m2 of capillary mats can be planned per each hydraulic circuit.

You can find manifolds suitable for the Hydro capillary system in our Product catalog, or send our our email:info@greatabiotechnology.com

The connection of the capillary tube mats to the manifold is made with welded PPR pipes PN10 and fittings of the required diameter.