Greata is a high-tech enterprise specializing in the development and production of capillary tube mats in China, with a tradition of more than sixteen years.

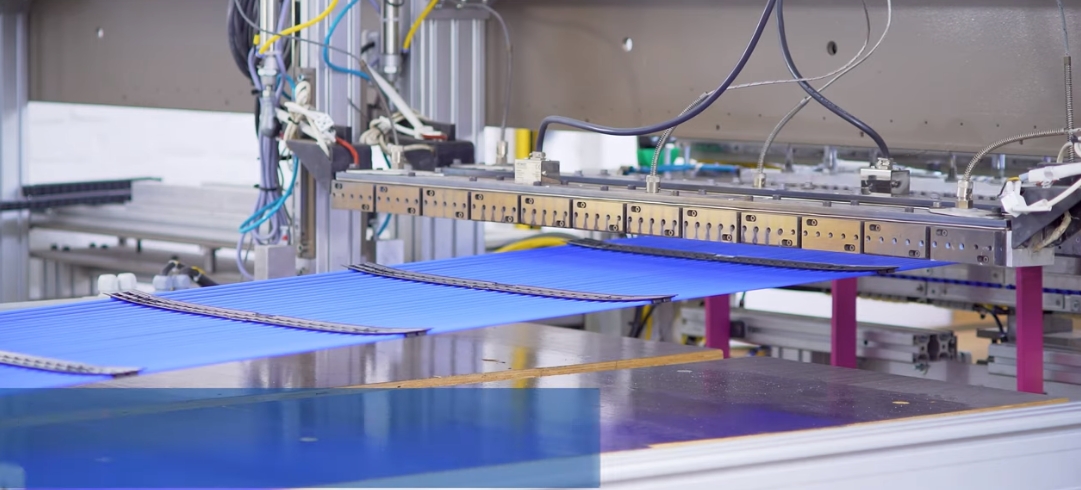

We use only high-quality PPR raw materials and German automatic capillary tube mat production line. The unique welding process and mature production experience ensure that each piece of the capillary mat has the same high quality.

The excellent stable product quality and thoughtful service win the customers’ trust. It also makes us the largest and strongest manufacturer of capillary mats in China.

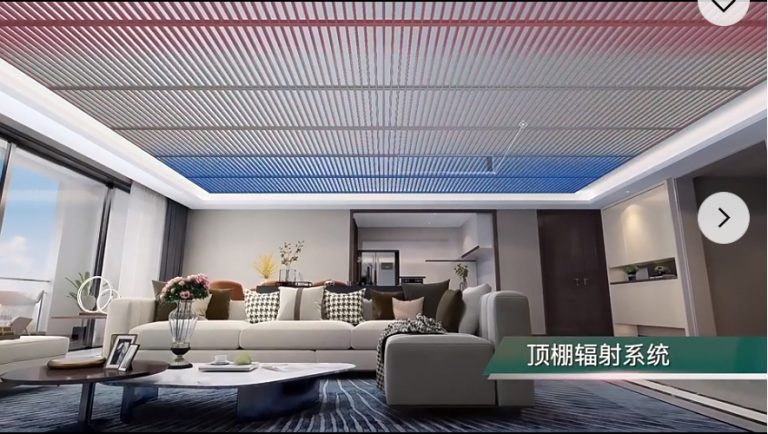

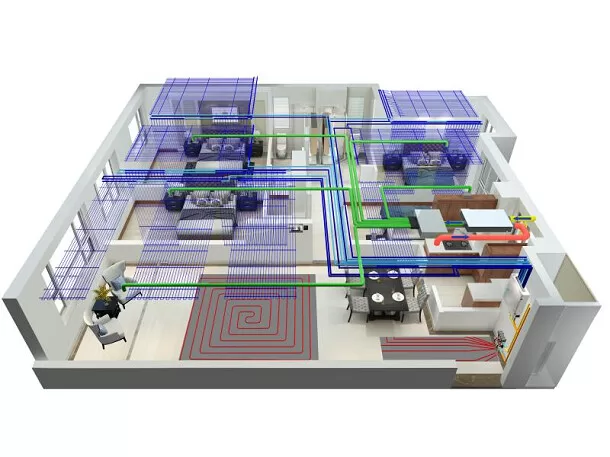

We can produce various types of capillary tube mats to meet the requirements of refrigeration and heating systems

Greata CAPILLARY TUBE MATS , TECHNICAL DATA

- Material: Polypropylene

- Tube Size: Main tube: 20 x 2.0 mm (PN 10) Capillary tube: 4.3 x 0.8 mm

- Mat Size: Width: max. 200-1000 mm

Length: max. 12000 mm - Distance between capillary tubes: 10 mm~20 mm

- Pressure:

Test pressure: 20 bar

Operating pressure in capillary system: 4~ 6 bar - Temperature:

For heating: 28 ~ 32℃

For cooling: 16~ 19℃ (above the dew point)

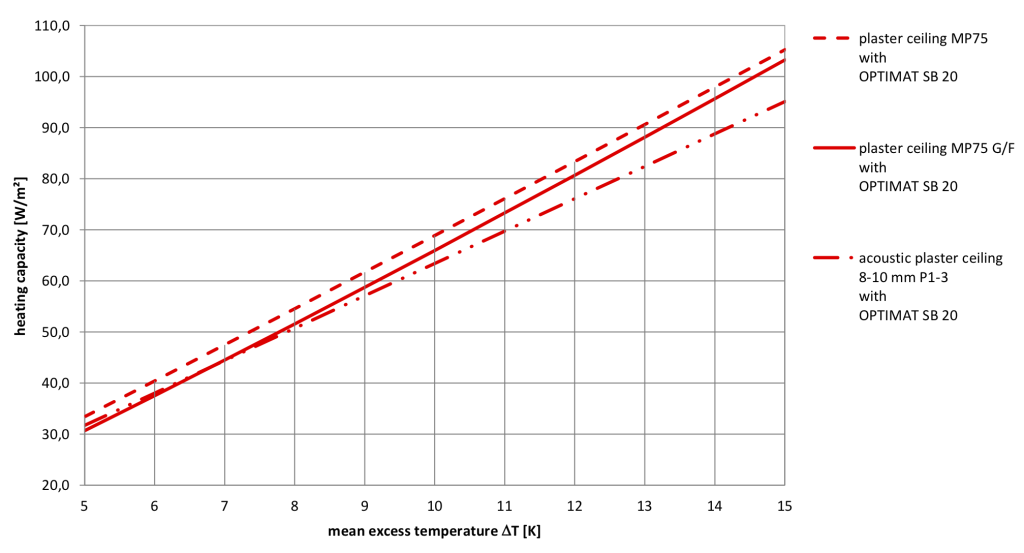

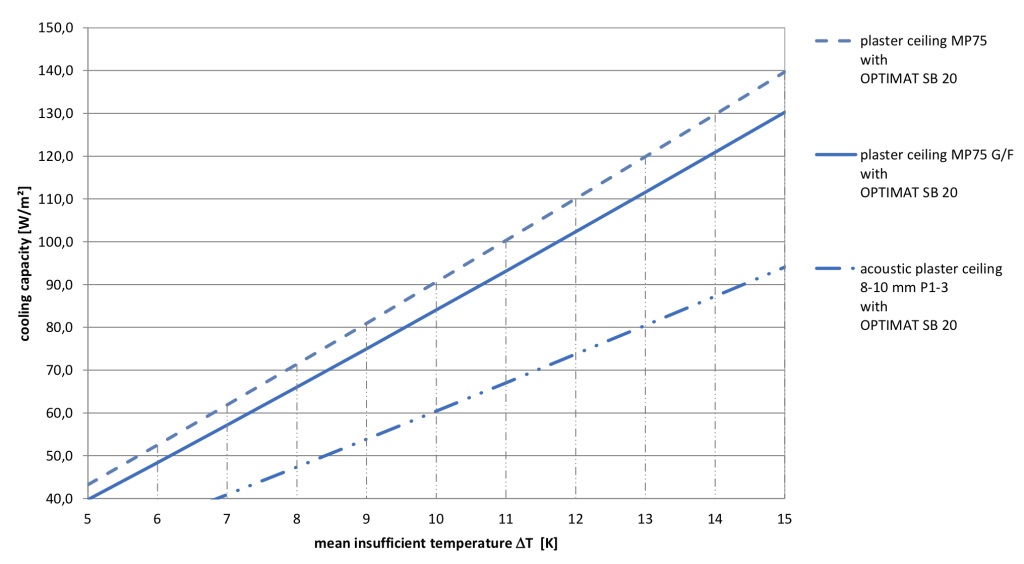

Max. temperature allowed in system: 55℃ - Heating/Cooling Capacity:

Underfloor heating : 100 w/m2

Wall heating capacity: 100 w/m2

Wall cooling capacity: 80 w/m2

Ceiling cooling capacity: 90 w/m2

(The specific capacity depends on the supply water temperature, installation types and related conditions.)

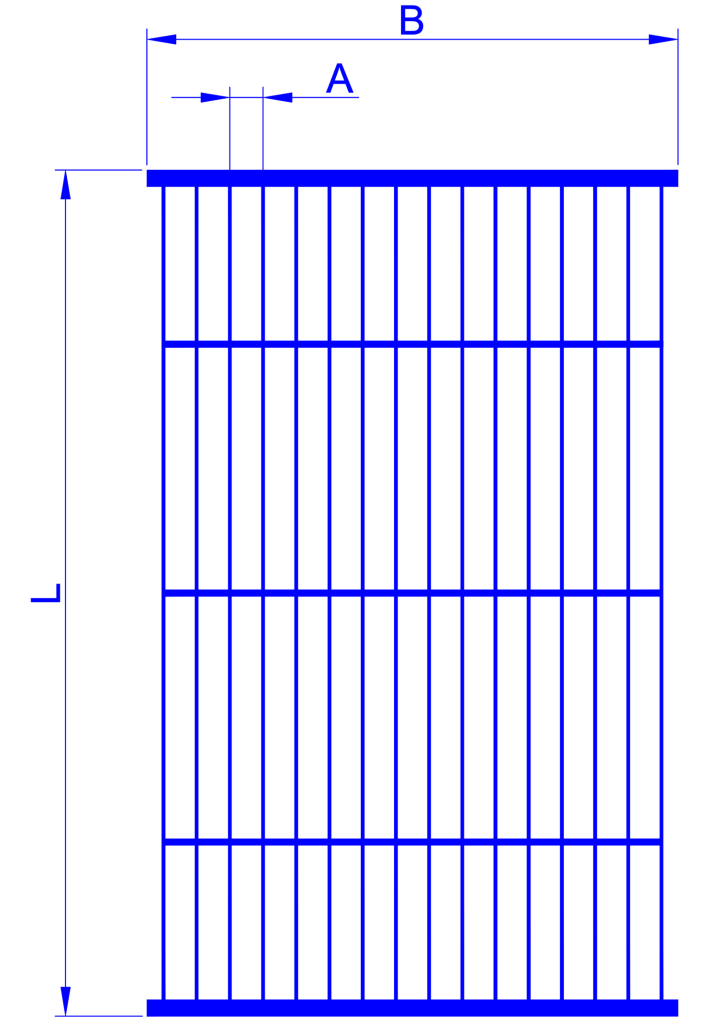

Type H mats

Type U mats

U IMAGE

Advantages Capillary Tube Mats System

- Energy efficient

Water supplied in capillary tube mats only requires 28-32℃ for heating purpose, it reduce heating energy consumption compared with the 45-60℃ request of common floor heating pipes. It has tested the capillary system can save 30-40% consumption.

For cooling in summer, the supply water is around 16-18℃ which is much higher than the traditional air conditioner.

It can save 50-60% energy consumption. The combination of capillary tube mats with heat pump can achieved the highest outputs. - Space saving & Easy installation

Within the construction, the thin capillary tubes mats with an outer diameter of 4.3 mm only be covered with leveling or sealing compound of 10mm thickness.

The high flexibility of the greata capillary tube mats technology enables easy installation even in the most diverse structures. - long life & Free maintenance

All greata capillary tube mats are produced under strict quality control with a top level of precision and safety. No maintenance required with high quality the using life of capillary mat is around 50 years - Environment friendly

The raw material is Polypropylene- high quality, environmentally friendly and safe plastic with excellent physical characteristics and highly recyclable. - Rapid reacting

The limited thickness minimizes the thermal resistance and leads to the heating reacting rapidly to temperature changes in just a few minutes and achieving high specific heating capacities.

- Healthy & Comfortable

Greata capillary mats realizes the heat exchange in a form of radiation with gentle and even temperature changes,draughtfree and noiseless. - Various Energy Solution

Greata capillary tube mats can be connected with air source heat pump, water source heat pump, ground source heat pump, solar energy, etc.