pipe cooling mat -ice rinks mat

Industry-specific attributes

Processing Service

Moulding, Cutting

Other attributes

Place of Origin:Jiangsu, China

Brand Name: Greata

Model Number :ICE-100

Product name :ice rink mat

Operation Pressure:0.5-2.5Bar

Operation Temperature :-45C to + 120C

Size:117*9*6mm ,123*12*8mm,131*12*8mm

Application:Outdoor Recreation(Removable ice skating mats)

Packing:Carton Box

Color:Black or white

Suitable places:Outdoor Location

Feature:Flexible

Material:ICE-EPDM,NBR+PVC

Packaging and delivery

Packaging Details

1roll/ctn,export carton

Port:Shanghai,Shenzhen or guangzhou port

Supply Ability

Supply Ability:100000 Meter/Meters per Month

| Product name | Ice rink mat | Working life | Long life |

| Material | ICE-EPDM Rubber orNBR+PVC | Application | skating ice rink flooring hose |

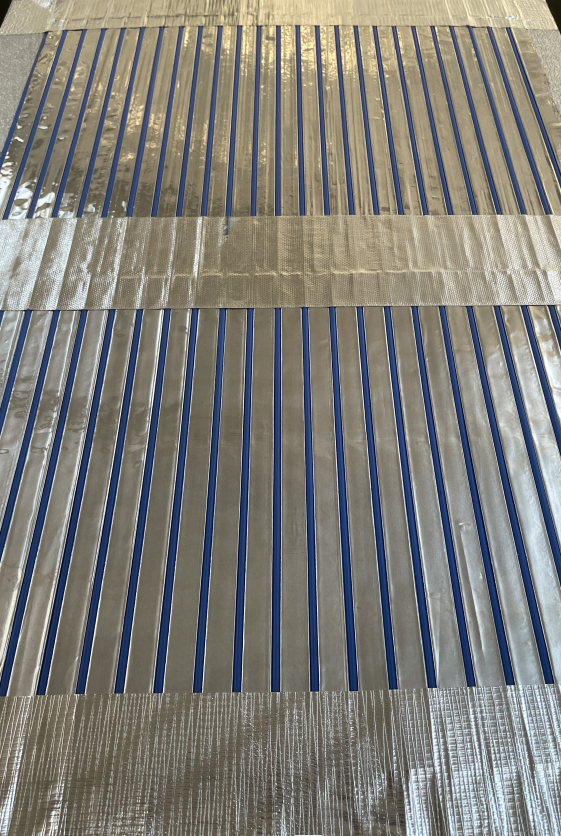

| Size | rubber mat with 8 hose117*9*6mm131*12*8mmRubber mat with 6 hose115*14*9mmrubber mat with 4hose 90*15*11mm | Color | Black :ICE-EPDM White:NBR+PVC |

Introduction for the ice rink mat

Mobile Ice Rinks:

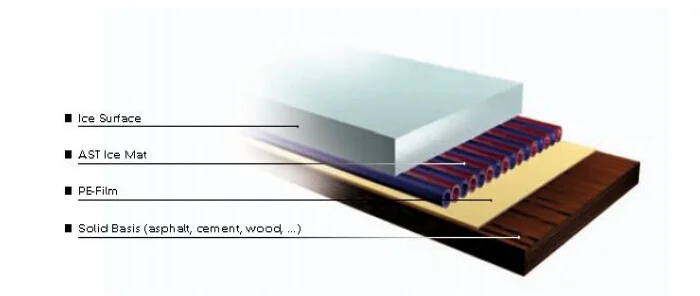

1. The Concept of an Artificial Ice Rink

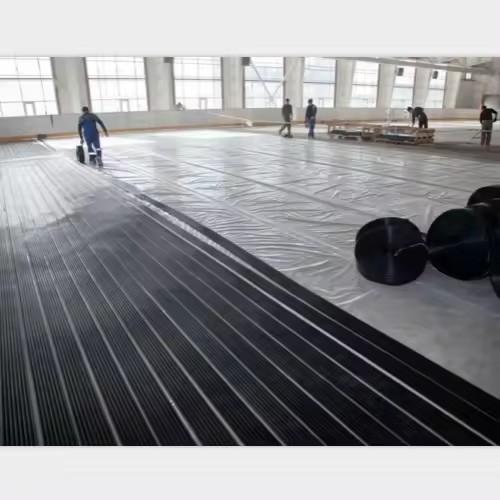

1) The Absorber strips (Ice Mats) are rolled out side by side to

form an area which will become the ice surface.

2) An environment-friendly mixture of antifreeze and water is then

chilled by a refrigeration unit to a temperature of between -7°C

and -10°C and pumped through the ice mats.

3) The temperature of the ice mats falls below the freezing point

which then freezes the sprayed on water into a smooth and uniform

ice surface.

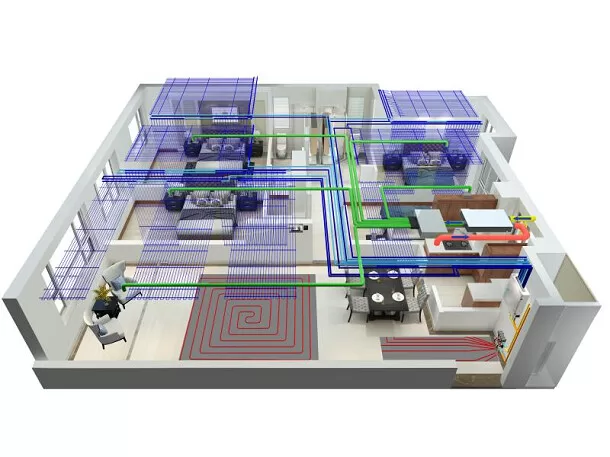

2. An Artificial Ice Rink Consists of:

1)Absorber Area ( Ice Mats)

2) Refrigeration Units

3) Ice Area Boarding

4) Ice Resurfacing Machines

5)Accessories

6) PE-film

7) Solid Basis (asphalt, cement, wood, …)

3. Ice Mat Technical Data

1)Material: EPDM

Absorber width: Single strip width 117 mm consisting of 8 tubes

2)Absorber Length: Variable

3)Absorber weight: 510g/m

4)Empty: 5,5 kg/m2

5)Full: 8,5 kg/m2 – contents 3,0 l/m2

6)Flow Rate per m2: 50 to 100 l/h

7)operational Pressure: 0,5 to 2,5 bar

8)Temperature Resistance: -45°C to + 150°C

Ice rink concept

1. The absorption tower band (ice pad) is pushed out side by side to form an area that becomes the ice surface. 2. An environmentally friendly mixture of water and antifreeze is chilled to temperatures between -7°C and -10°C by a refrigeration unit and pumped into the ice pad. 3. the temperature of the ice pad is below freezing and then the spray liquid is frozen on the water to form a smooth and uniform ice surface.

1.The width of Ice-skating mat : width is 125 mm 8-tube composition

2.The length of Ice-skating mat : depends on ice rink

3. The weight of Ice-skating cooling pipe mat : depends on length

4.Temperature resistant :-40~+60 ℃

ice making equipment

In order to operate an artificial ice rink, a refrigeration unit and circulation pump are necessary. The refrigeration unit provides the necessary cooling energy which is then transferred to the antifreeze/water mixture. By means of a circulation pump, the mixture is chilled to -7°C and -10°C and then forced into the absorption area.

Ice Rink Epdm Mat

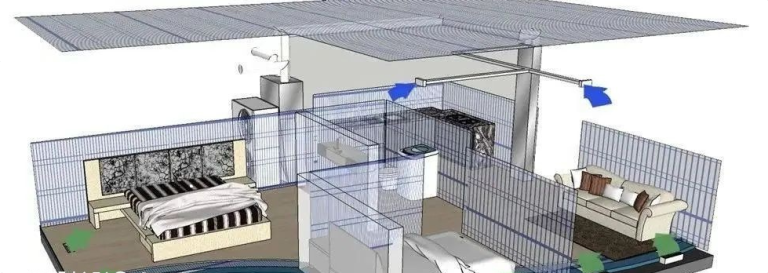

EPDM ice mats for mobile ice rinks are unique set of (greata ice system) modules combined into the flexible absorbing heat exchanging cooling surface. Serial connection of the AIS modules, made up of segmented EPDM ice mats, connected to the collector tubes installed in a portable steel construction covered with aluminium-coated anti-slip plates, enables the construction of any tailor-made ice rink.

greata modules are manufactured in 2.5-metre-wide sections, while their length may vary, from the prefabricated ones (20, 30, 40 and 50 metres) to any other custom-made dimensions, according to the size of the location. This type of ice mats are most commonly used for mobile ice rinks, but can be applied to permanent and multi-functional ice rinks as well. EPDM ice mats have a high energy efficiency, meaning that they can be used for the production and maintenance of flawless ice, from the moment ice is made, with minimal power consumption of the refrigeration unit.

The advantage of ice rinks mat

1. Because the mat is flexible, it easily adapts to the ground. Obstacles such as fountains, trees, street light poles, etc. are not affected.

2. Because the total base point of the rink construction is low, less water is needed. Energy can be saved.

3. The narrow tube layout of the ice pad produces an energy transfer of 2 square meters per square meter of ice area. This results in a cooling time consistent with a uniform ice surface.

4. Due to the tight separation of the pipes, energy efficient instant heat transfer to the rink surface has created greater value. So the end result is a rink system that is 35% more efficient than traditional heat transfer media, uses less refrigeration and glycol, and makes more money.

5. Due to the unique design of the Instant Rink, it takes less than 30% of the time to install and dismantle a traditional rink, in addition to the actual energy costs, labor is the most expensive. The Instant Rink will only pay for itself in two quarters, which is achieved by reducing the consumption of materials and labor.