Advantages of capillary tube mat

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

Description

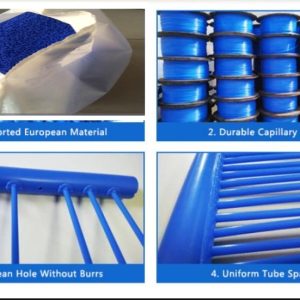

Capillary tube in good High flexibility, diverse application possibilities

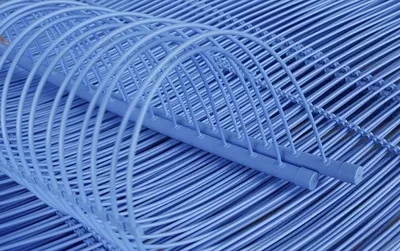

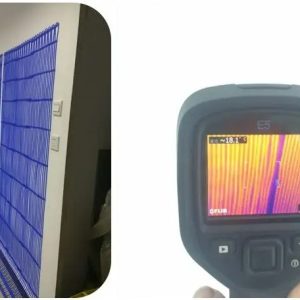

Capillary tube mats can be built into all standard ceiling constructions. The fine dimensions of the capillary tubes with an outer diameter of only 3.5 mm give the capillary tube mats a high degree of flexibility. This flexibility also enables problem-free installation in structures that deviate from the standard. Even the thermal activation of vaulted and curved ceiling structures is possible with capillary tube technology.

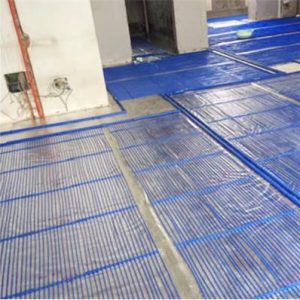

There is also a wide range of different types of capillary tube mats. Depending on the application, capillary tube diameters and spacing between the capillary tubes vary, so that suitable types of mats are available for heating and cooling ceilings, wall heating, underfloor heating or for use as surface collectors. Our selection of special applications further illustrates the many possible uses of capillary mats as heat exchanger. The capillary tube technology can be applied equally for new buildings or for the modernization of residential and office buildings.

Additional advantages in safety, maintenance and quality:

- Limestone does not occur in water capillary mats; limestone forms at +60°C – the water in the water capillary mat system is at max. +32°C for heating and at max. +18°C for cooling.

- Mud does not occur in water capillary mats; mud results from corrosion – the water capillary mat system uses only corrosion-protected components made from PPR, stainless steel, brass or bronze.

- Prior to operation, the safety of the water capillary system is verified with air pressure at 20 bar and water pressure at 10 bar; the system is filled only once.

- Water capillary mats can be easily repaired; a capillary is cut and both ends are welded – with no effect to the heating/cooling output.

- Water capillary mats do not require maintenance and have a safety guarantee of up to 50 years.

Technical Data:

| Material | Type 3 polypropylene random copolymer, DIN 8078 |

| Collector pipe Ø | 20 x 2 mm |

| Collector tube Ø | 3.5 × 0.5 mm |

| Capillary tube spacing (A) | 15 mm,10mm |

| Lenght (L) | 750 – 7,000 mm (in 10 mm increments) |

| Width(B) | 170 – 1,200 mm (in 10 mm increments) |

| Mass when filled | 824 g/m² (without collector) |

| Exchange surface | 1.067 m²/m² |

| Water content | 0.39 l/ m² |

| Cooling capacity* | 83 W/m² |

| Permissible heating water temperature | 60°C |

| Operating pressure | 4 bar |

| Connection for butt and socket welds | 00 (without connections) |

| Field of application | Metal acoustic ceiling systems |

*Capacity achieved under defined conditions