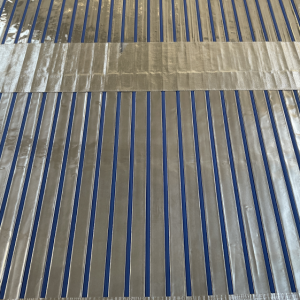

Construction process of capillary tube mats

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

Description

Construction process of capillary tube mats

1. Treatment of the original roof and wall surface

Currently, most of the villas, apartment buildings, and other projects in contact with construction have walls and top surfaces painted,

If the building structure does not require insulation treatment, before the construction of capillary engineering, it must first

Request the owner or decoration company to clean up the original wall and top surface paint before we proceed

Installation and construction of capillary tubes.

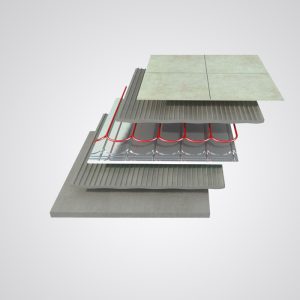

2. Treatment of insulation roofs and walls

When the developer or owner inside the building has already prepared the structural insulation layer, it is necessary to

Clean the dust on the working surface first to prevent hollowing and bubbling of the plaster after the capillary tube is attached

as

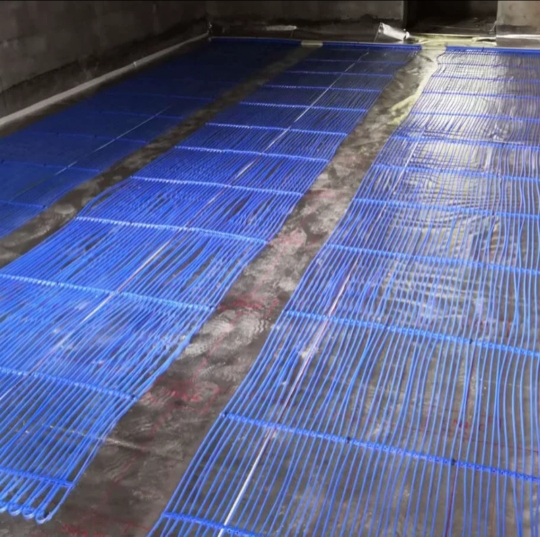

3. Ground treatment

The ground for installing capillaries must be cleaned before construction, and a thickness of 20MM must be laid on the ground

Place a reflective film on the benzene board, and then lay a 10 * 10 wire mesh on the reflective film to

Fix the capillary network.

2、 Installation of pipelines

1. Installation of elevator

The capillary network system pipes are mostly made of PE or PP-R pipes, which are lightweight, pressure resistant, and resistant to

It has advantages such as corrosion, low resistance, long service life, simple construction, and non-toxic cleaning, but at the same time, it also

There are characteristics such as relatively poor rigidity and large linear expansion coefficient, which are prone to pipeline deformation during use

Due to the shape issue, the installation spacing of the pipeline support elevator is particularly important. According to multiple construction sites

Work experience, using plastic or galvanized iron sheet to hold clamps in engineering, and lifting the spacing between capillary pipe clamps