A geothermal reservoir with capillary tube mats is a system that utilizes capillary mats to enhance the heat exchange and efficiency of a geothermal reservoir.

In a typical geothermal reservoir, a fluid (often water) is circulated through underground pipes or wells to extract the heat from the earth’s crust. This fluid transfers the heat to a heat exchanger, where it is used for various applications like heating or power generation.

A capillary mat is a porous material made of fibers that have capillary action properties. These mats can absorb and distribute liquids through capillary forces, allowing for efficient transfer of heat and moisture.

In a geothermal reservoir with capillary mats, the capillary mats are placed around the geothermal pipes or wells. As the geothermal fluid flows through the pipes, the capillary mats absorb the heat from the fluid and distribute it across their surface area.

The capillary mats act as a secondary heat exchanger, increasing the contact area between the fluid and the surrounding environment, which enhances heat transfer. This leads to improved overall efficiency of the geothermal system.

Another benefit of using capillary mats in a geothermal reservoir is the moisture retention capability. These mats can absorb and retain moisture, allowing for better humidity control in the surrounding area. This is particularly useful in applications like greenhouse cultivation, where maintaining the right moisture levels is crucial.

Overall, a geothermal reservoir with capillary mats can improve the heat exchange efficiency and provide better moisture control, making it a more sustainable and efficient option for geothermal energy extraction.

Geothermal energy recovery

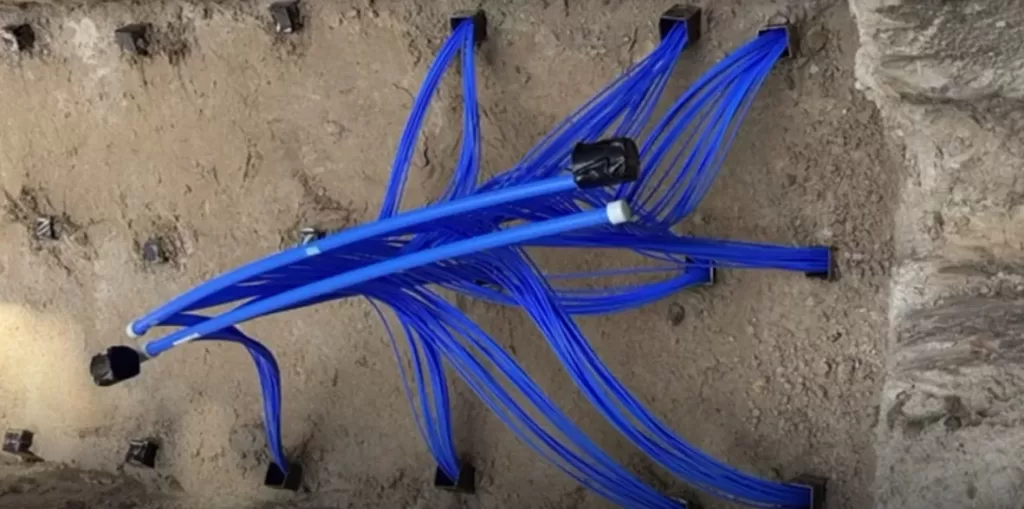

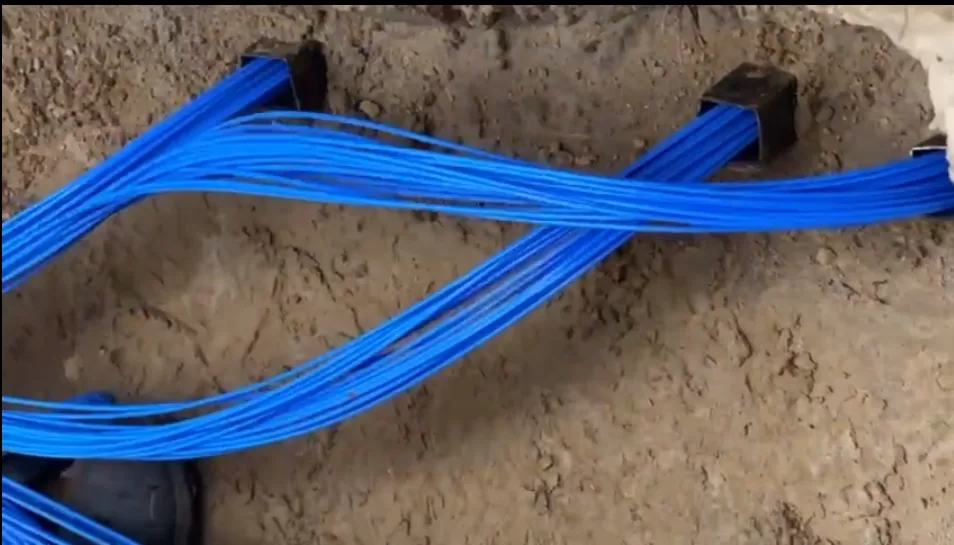

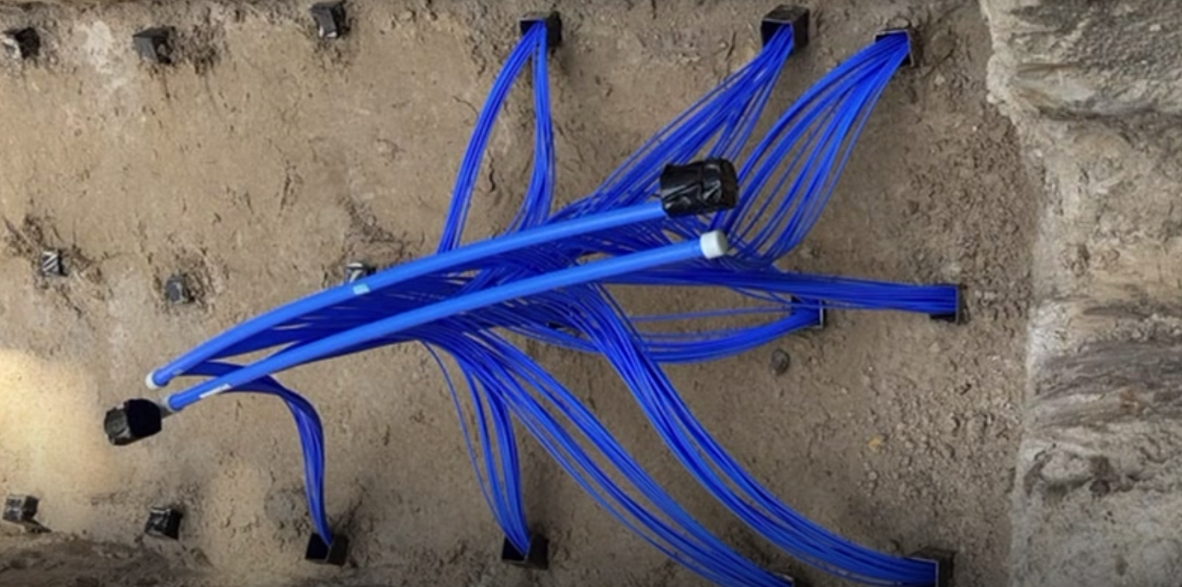

External GEO circuit from water capillary mats in two ways:

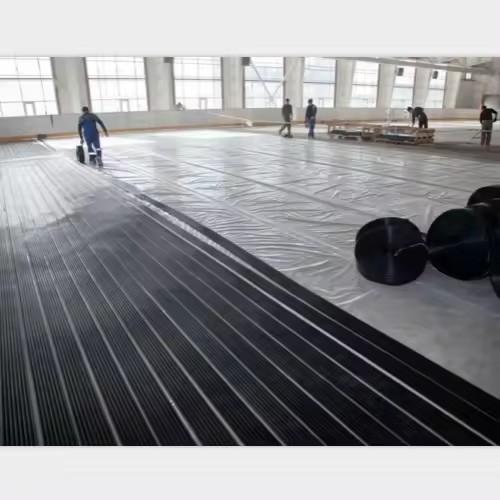

GEO “slab” (composite reinforced concrete)

Can be installed under first/ground floor covering (depth 0,5-0,7 m), with potential power (30-40 w/m2), the solution is mostly intended for buildings with Zero or almost Zero energy consumption and in places where there is no free land or the possibility to dig or drill deeper.

HK-eTank (eBasin)

Consists of capillary 3D-modules, buried at the depth of 1.5-2 m, with potential capacity 50~80 w/m2, depending on the groundwater.

Indicative example

Initial data: baseless energy efficient building, with consumption up to 39 kW/m2 per year.

Assumed outdoor air calculation temperature:

- in the cold period -20,7°C;

- in the warm period +27 °C, RH=60%

Heat carrier parameters when the heat pump is running:

- underfloor heating system +26-31°C

- ventilation heating system glycol 35% +30-40°C

Coolant parameters when the heat pump is running:

- ventilation cooling system glycol 35% +15-18°C

Coolant parameters, when the GEO circuit is running:

- ventilation cooling system glycol 35% +19-21°C

- underfloor cooling system +19-21°C

The heat-cold supply of the building is performed from a heat pump with a ground circuit, which works together with the underfloor water capillary heating system, which is also intended for “gentle” floor cooling, covering (absorbing) heat emissions with a coolant temperature of +19-21°C.

Cold source for cooling the building – the ground circuit of the heat pump, consisting of water capillary mats embedded in a 150 mm thick horizontal composite reinforced concrete slab, under an insulated floor. This type of installation is suitable for buildings with low energy consumption and in cases where it is not possible to build an external circuit.

Standard ĢEO circuit consists of a network of wide “3-D” modules of water capillaries, which are mounted at a depth of 1.5 m.

The heat-cold power of the GEO circuit varies from 34 līdz 70 W/m2 (capillaries), depending on local conditions and type of installation.

During the warm period of the year, the cold ground temperature (+8-12°C constantly) is “transported” to the floor capillary system and the ventilation unit pre-cooler (without the use of a heat pump compressor, only electronic circulation pumps). In this way, the ground circuit, which was cooled during the heating period, is heated during the summer, restoring the balance of thermal energy in nature. The annual SCOP can reach up to 8,9 W/W.

By taking full advantage of energy devices, it is possible to reach a level very close to the characteristics of a self-sufficient, passive house.