Radiant heating and cooling in general

The dispatch of the goods is clearly coordinated with the executing trade before the forwarding agent or the transport service provider takes over the goods from us. Reliability in terms of product quality and binding delivery times are a key concern for us. We want you to be able to carry out your project without delay and with high quality craftsmanship.

What durability does the system have?

50 years and longer – standard operation conditions for radiant heating and cooling provided.Which capacity do cooling ceilings with capillary tubes reach?

Always sufficiently enough! In standard installations the following capacities are reached (values tested according to EN 14240):

plaster ceiling: 76 W/m2

plasterboard ceiling: 68 W/m2

metal cassette ceiling: 89 W/m2

In the end, the engineer always chooses the right cooling ceiling type in a concrete project considering the actual cooling capacity requirements and ceiling construction.

What can I do to reach more cooling capacity?

Even more cooling capacity? No problem! Only the ceiling construction and temperature difference ΔT between average water temperature and room temperature affect the cooling capacity of a radiant cooling ceiling. Besides raising ΔT, also the convective capacity of the ceiling can be raised by forced or artificially controlled convection. Higher convection can be reached for example by open ceilings or floating ceiling panels.

In this way, cooling capacities of up to 180 W/m2 are possible.Can I use a cooling ceiling system also for radiant heating?

Naturally, a cooling ceiling system can also be used for heating! Instead of cool water, you only send warm water through the surfaces activated by capillary tubes mats or serpentine copper tubing or the single pipe technology.With what water temperatures does the system work for radiant heating?

28°C will usually suffice.

Radiant heating and cooling with capillary tube mats

Is it possible to repair a leaking pipe during or after the installation?

Leaking pipes or fittings are not a problem. It is very simple to repair the leaks. First run the water through the mats in order to see a wet spot on the drywall or plaster. Open this damaged areas, than fused the piping on both sides. This will not affect the capacity for cooling or heating.What is to do before the start up of the capillary system?

Before the system entry into service the system should be tested against leakiness.

That happened via an air pressure test of 12 bar. In the second steep you do the same test with water.

If you find any leaks it is very easy to repair them.

Can you use the Mat as a Geothermal Absorber?

In general you can use the mat as an absorber. The attributes of Polypropylen do not aloud the direct contact with sunlight. The mats is to protect against direct UV-rays.How does the capillary tube technology work?

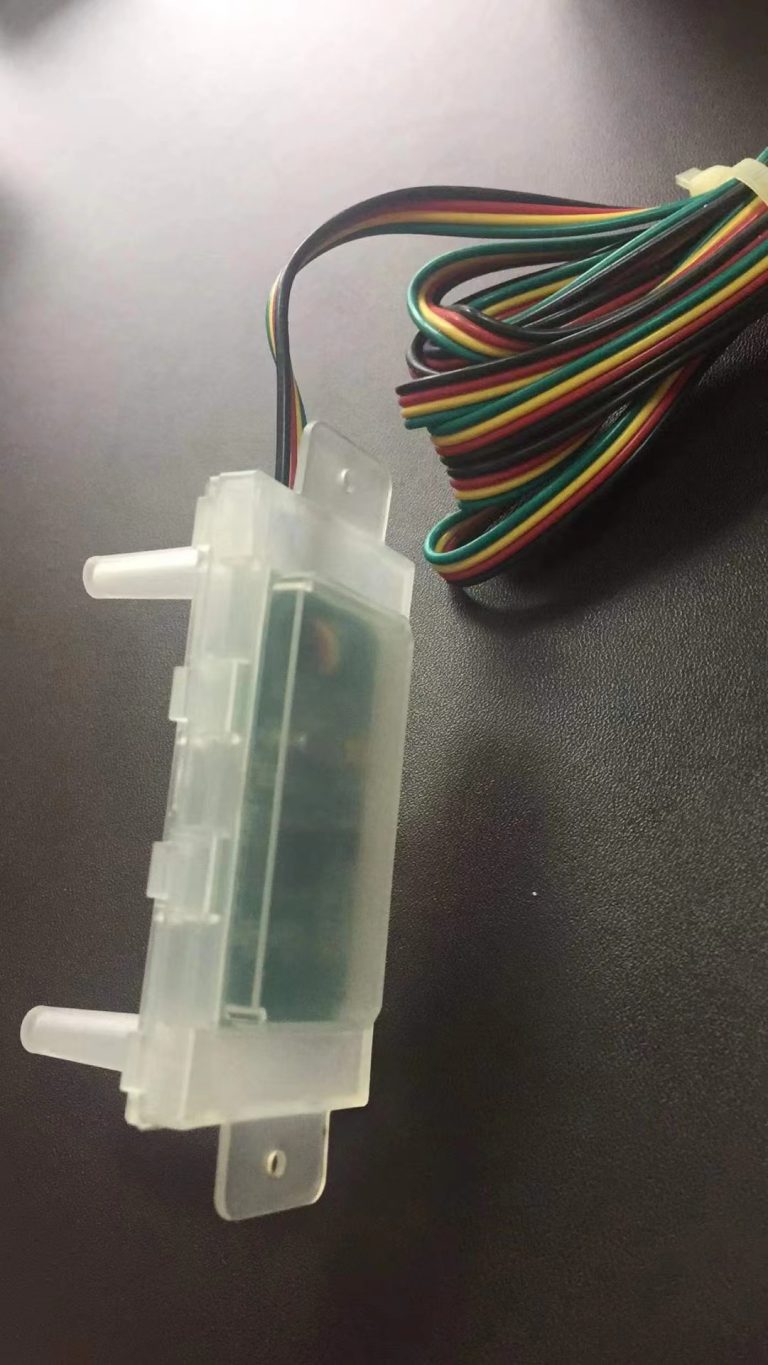

At the heart of the greata capillary tube principle is a closed system of thin tubes. Just like blood vessels are located directly under human skin, the capillary tube mats are located just under the surface of walls, floors and ceilings. Cool or hot water flows through the network and supplies the rooms with pleasant temperatures.

In the same way that blood circulation gives life to people, greata capillary mats give thermal life to buildings.Can I connect the capillary tube system to an existente system?

Yes, you can! By using a heat exchanger you can integrate the capillary tube system in every installation. By using non corrosive material in combination with capillary tubes mats you have a very long lasting system.

capillary tube mats for the realisation of radiant heating / cooling systems in the best quality

Whether plastered cooling ceilings, radiant ceilings with metal cassettes or plasterboard, whether wall heating or thin-layer underfloor heating – greata offers heating and air-conditioning technology companies the suitable system components from its own production for each of these technical tasks.

Project-specific adjustments to the modules are also possible in terms of dimensions and design. All of our capillary tube mats are manufactured to strict operational quality assurance standards. The individual production steps are continuously checked, and at the end of the production run a final test is carried out again. That’s why we guarantee a 15-year warranty on greata products.