Welcome to greata

General FAQs for capillary tube mats

-

CAPILLARY TUBE MATS FROM greata

-

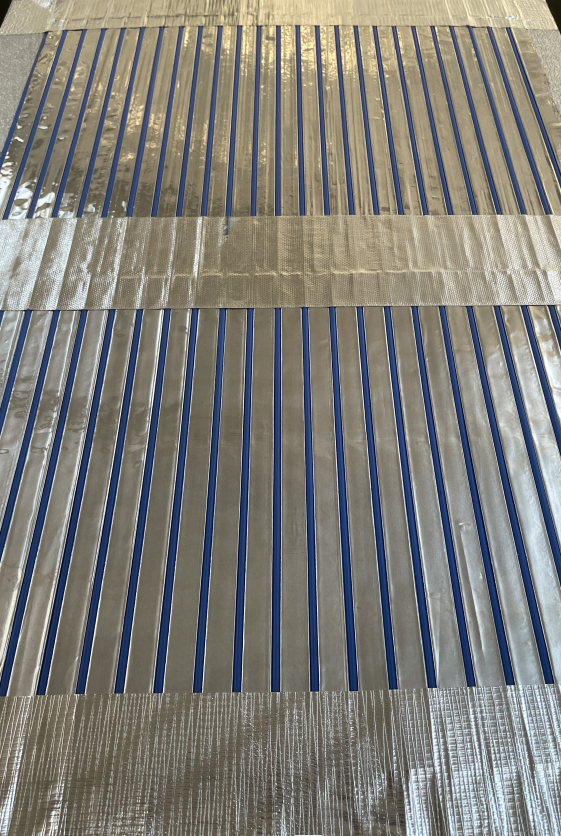

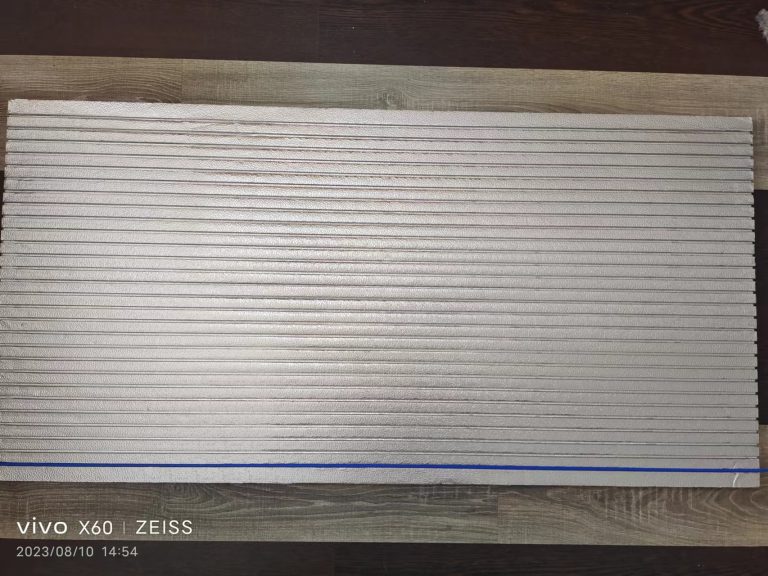

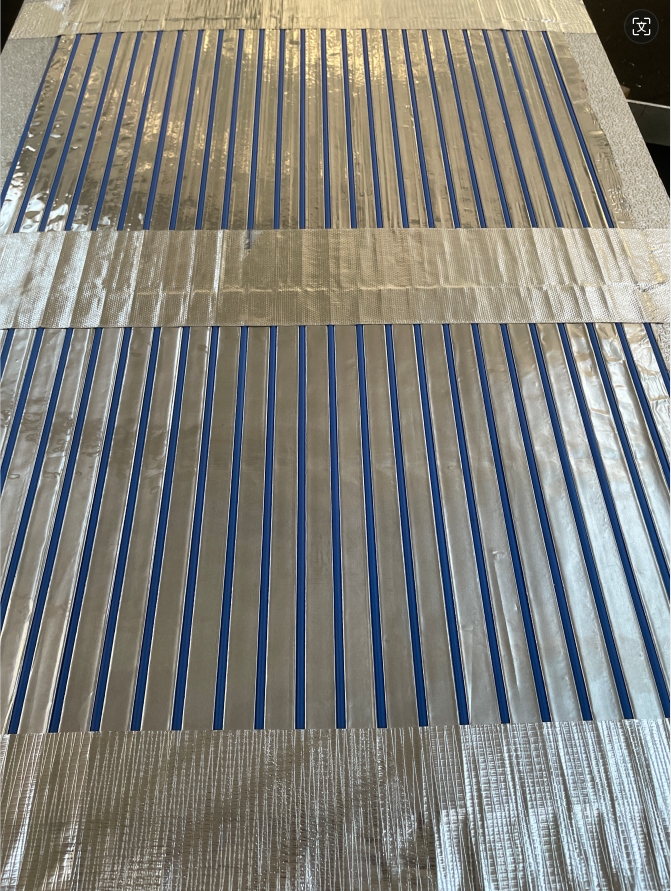

BASIC SHAPES OF GREATA CAPILLARY TUBE MATS

-

ADVANTAGES COMPARED TO THE SINGLE-PIPE SYSTEM

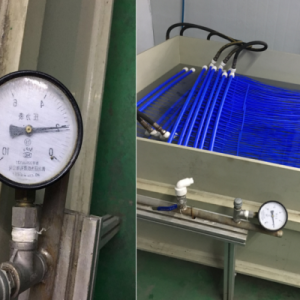

All Greata capillary tube mats are made in China from high quality polypropylene according to the ISO 9001 and CE standard. Constantly further developed production machines and a unique welding technology for connecting the capillary tube with the mat distributor pipes ensure a very high quality standard and allow a long-term guarantee. Every single product is subjected to an intensive quality control and we will offer a testing report, before it leaves the company.

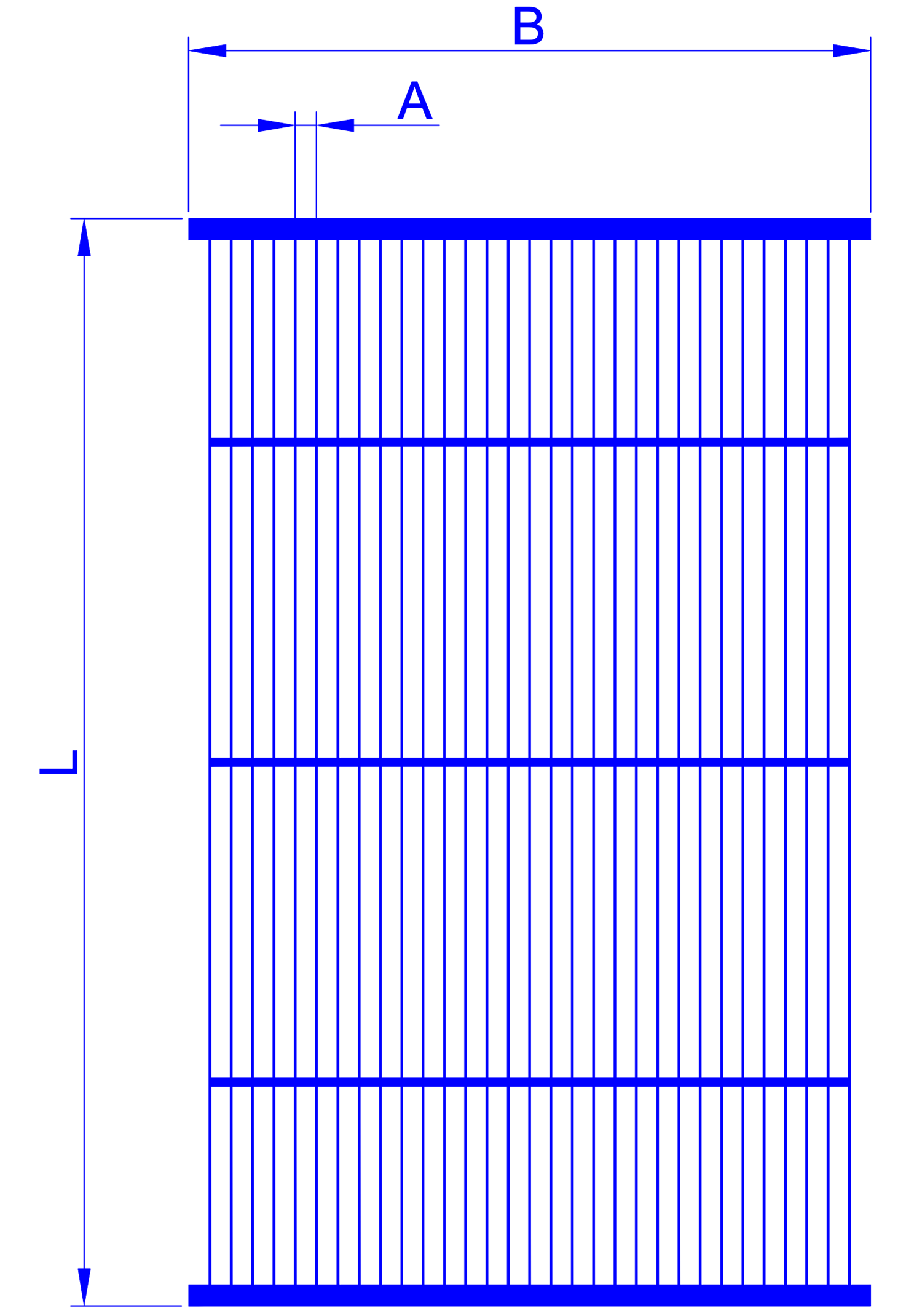

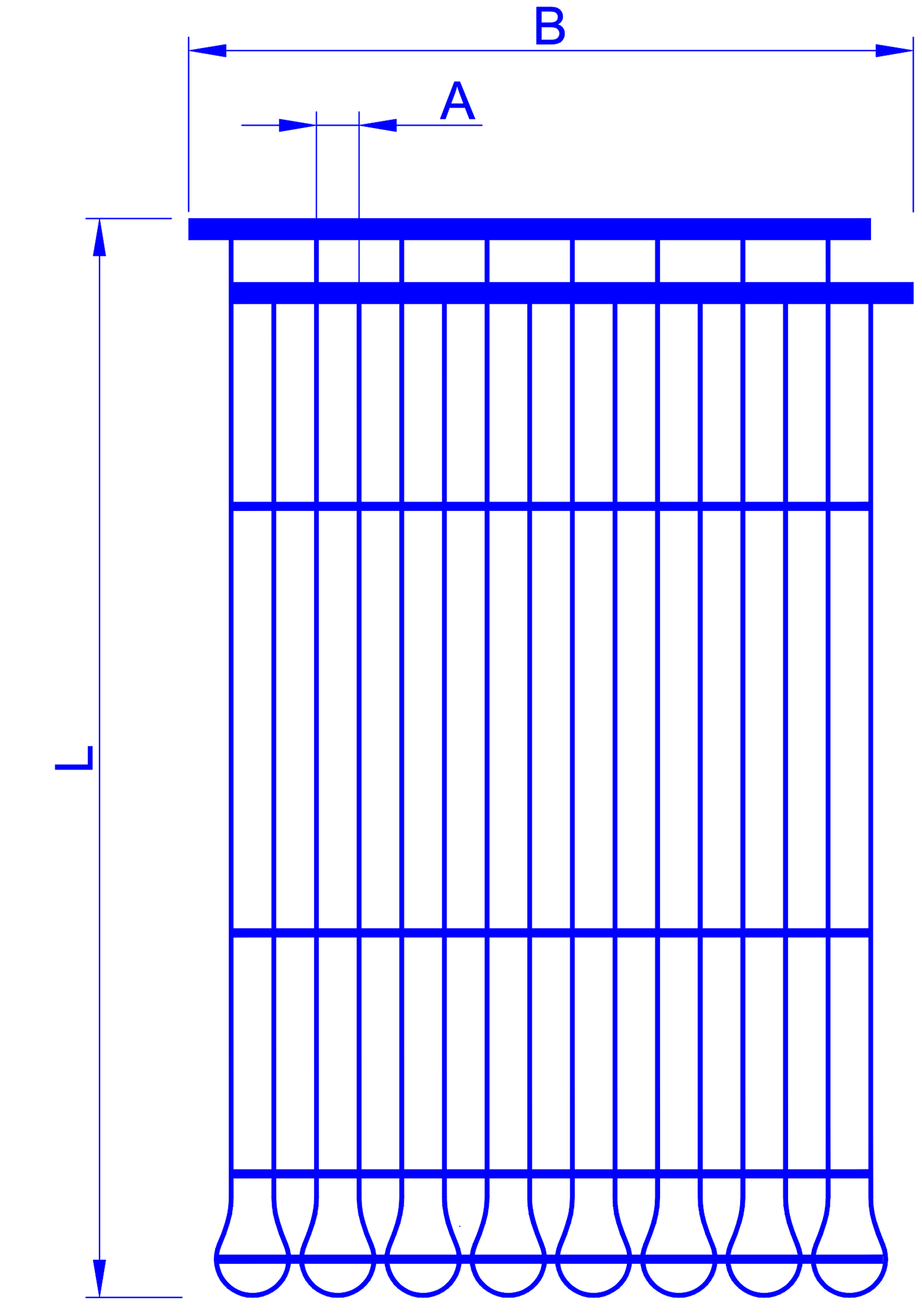

BASIC SHAPES OF GREATA CAPILLARY TUBE MATS

G – MAT | S – MAT | |

|---|---|---|

|  | |

| G = STRAIGHT MAT | S = MAT WITH LOOPS |

The capillary tube mats with a parallel flow have the following excellent characteristics:

- low pressure loss (cost reduction of circulating pump)

- high dynamics (short reaction times of just a few minutes)

- large heat exchange surfaces because small distances between the capillary tubes (even heat distribution on the surfaces)

- small differences between system and ambient temperature (high efficiency,energy saving, )

- high heating and cooling capacities

- light weight

- very flexible (e.g. suitable for curved surfaces)

These characteristics ensure, among other things, a room temperature control with most comfort & well-being.