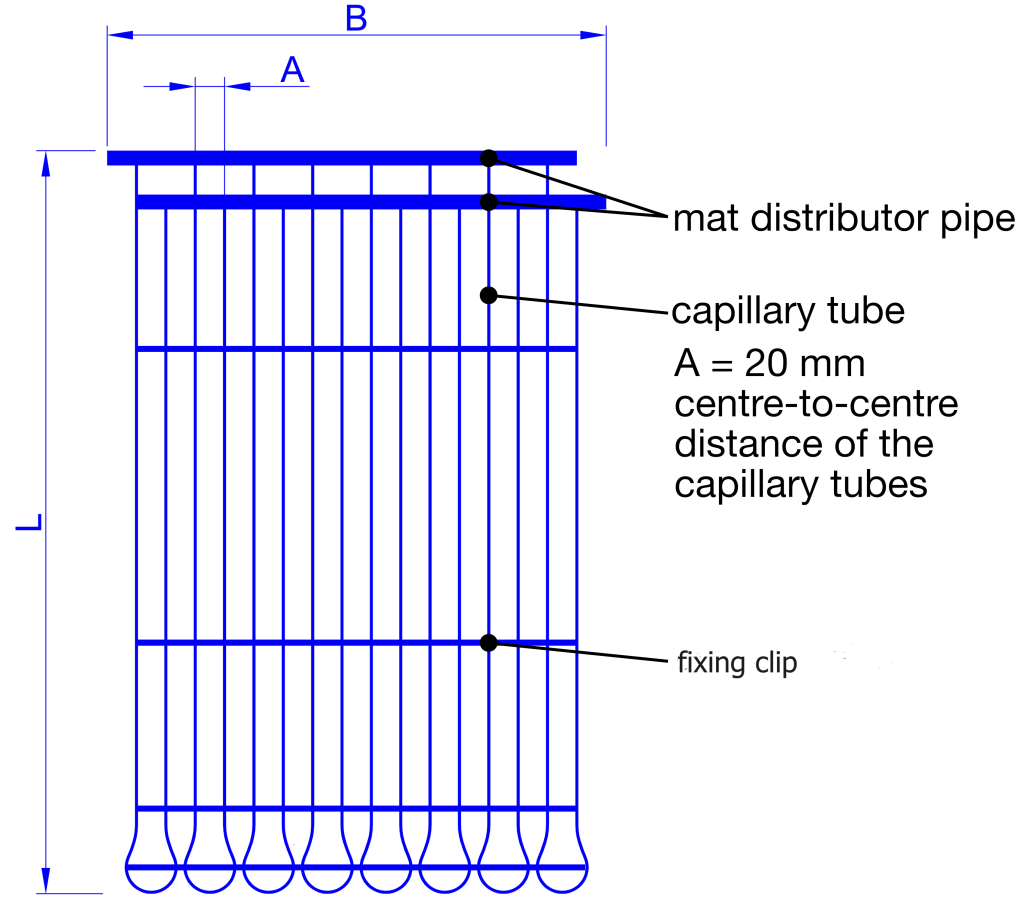

Capillary tube mats

- Capillary tube mat for use in surface heating and cooling system, has capillary tubes with ends attached to through-holes formed in strain pipe, and tapered transition region extending from inner surface of pipe into respective through-hole

- Thin net for air conditioning system with independent heat and humidity treatment

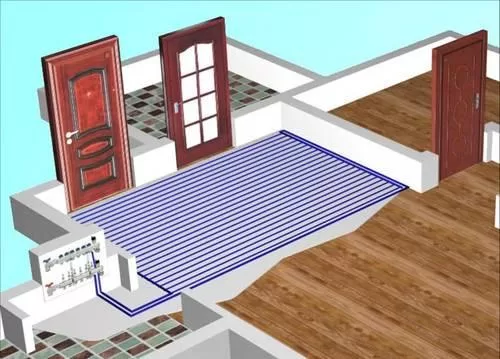

- The capillary network is used in the air conditioning system with independent heat and humidity treatment. The capillary network is thin and flexible. As the radiation terminal, it can be used for heating and cooling. The system needs to be used with the fresh air system when cooling.

- The mesh grid composed of 4.3×0.8 mm PPR plastic capillaries with a spacing of 10 mm – 30 mm is like the capillaries in the human body, playing the role of distributing, transporting and collecting liquids. The liquid flow velocity in the mesh grid and the human capillary is basically the same, between 0.05-0.2 M / s. At the same time, the capillaries of human subcutaneous tissue successfully conduct heat transfer exchange with the surrounding environment to achieve the purpose of self temperature regulation.

- In winter, the capillary tube is filled with hot water with low temperature to gently radiate heat to the room; In summer, the capillary tube is filled with cold water with high temperature, which gently radiates cold to the room. Because the capillary mat has a large heat exchange area and a fast heat transfer speed, the heat transfer efficiency is higher.

- Limitations of traditional plastic pipe connection:

- (1) Many pipe fittings are used, and the connection process is complex, which is prone to water leakage accidents.

- (2) The connection mode restricts the simultaneous connection of one integral pipe and at least three pipes.

- (3) The pipe wall thickness is limited. According to the existing national standards gb10798-89 general wall thickness table of thermoplastic pipes and jbj technical specification for floor radiant heating B.1.3, the wall thickness of thermoplastic pipes connected by hot melt shall not be less than 1.9mm, so as to ensure the reliability of hot melt connection, which limits the development of hot melt plastic pipes to small and micro diameter, The wall thickness of small-diameter pipes will far exceed the wall thickness requirements to meet the required pressure level, which not only causes waste of raw materials, but also reduces the flexibility and thermal conductivity of plastic pipes.

- Capillary tube mat processing is a technological innovation of plastic pipe processing technology

- (1) The utility model provides a connection method for directly connecting plastic pipes without adding straight pipes, elbows, tees and other connecting pipes.

- (2) A whole pipe is directly connected with several pipes at the same time through side opening.The wall thickness of the small pipe provided with end conection is not limited by the welding requirements, which makes it possible for the application of small and micro diameter pipes.