55 years for Grooved XPS foam board with Aluminium Foil with capillary tube mats

55 years for Grooved XPS foam board with Aluminium Foil with capillary tube mats

Factory price EPS Floor heating plate heating board Insulation Panels for floating floor board

| Description | EPS/XPS panel with pipe routing for Unferfloor Heating System | ||

| sizes | 120*600*21mm(L*W*H) or be Customized | ||

| Color | Various painting water-based colors | ||

| Advantages | 1. Specialized in this field for more than 50 years 2. Product quality: Strong QC team, strict quality control 3. OEM/ODM is warmly welcome. 4. One-stop window treatment and building materials supply service 5. Our experienced designer and engineers are familiar with your building code, and can always find the best solution for you. 6. All of our products are customized. 7. There are many choices to meet your various requirements. 8. Save your valuable time and purchasing cost. |

||

| Feature | Eco-Friendly, Super Lightweight, Other | ||

| Packaging | Paper Cartons Marks OEM | ||

| MOQ | 1 piece | ||

| OEM/ODM | Acceptable | ||

| Delivery Time | 15-20 Working days after deposit of payment | ||

| Payment Term | L/C, T/T, WESTERN UNION/ ESCROW | ||

| Homepage | |||

| Price | |||

How to Install Underfloor Heating Panel

1. The ground must be flat and clear

2. Tape the boundary strip

3. Laying the Underfloor Heating Panel

4. Install the pipes on the panel

5. Pouring and laying the concrete t o make the floor surface to be flat

6. Install the wood floor or tile

7. Some of our products could be no need pouring concreate, and install the wood floor directly For more details, welcome to contact us !

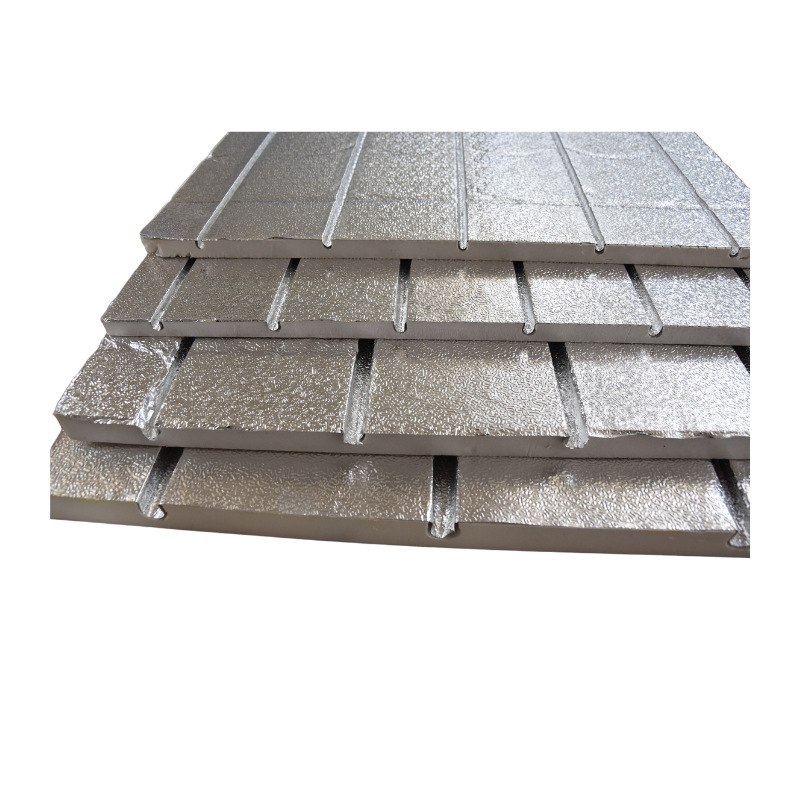

A grooved XPS foam board with an aluminum foil surface and capillary tube mats refers to a type of insulation material commonly used in construction.

XPS foam board is a rigid insulation board made from extruded polystyrene foam. It has a closed-cell structure that provides excellent thermal insulation properties. The grooves on the surface of the board allow for better installation of the capillary tube mats.

The aluminum foil layer serves as a radiant barrier, reflecting heat back into the building and preventing it from escaping. This further enhances the insulation performance of the board.

Capillary tube mats are typically made of plastic and have small tubes arranged in a grid pattern. They are used to distribute heated or chilled water evenly across a surface to provide radiant heating or cooling. The mats fit into the grooves on the XPS foam board, allowing for easy integration and enhanced performance.

Overall, a grooved XPS foam board with an aluminum foil surface and capillary tube mats combines excellent thermal insulation properties, moisture resistance, and radiant heat reflection to provide an efficient and effective insulation solution for buildings.