heating and cooling capillary tube mat system

Capillary tube mat -heating cooling system

capillary tube mat

Production Design

may be applied at :

> the ceiling

> the wall

> the floor (however, cooling needs the combination with wall or ceiling)

and is applicable for both new or old buildings, in particular in all monument-listed buildings for which an outside insulation would be excluded in view of their unchangeable façades.

DRYWALL CEILING WITH CAPILLARY TUBE MATS

The light capillary tubes lie directly on the top side of the plasterboard and thus pass on the heat without much loss. The low weight of an applied mineral wool insulation reinforces this effect.

Ceiling Cooling or Heating In Drywall with quick installation:

Installation of the substructure and a distance about 100 mm need be left between the support profile and the wall connection profile for inserting the capillary tube mats.

The main supply and return lines installation for the capillary tube mats in the ceiling void.

Hook in the retainers or retaining clips between the support profiles.The capillary tube mats are fixed between the support profiles of a suspended drywall ceiling with retaining brackets or retaining clips.

WALL RADIANT HEATING & COOLING

The light capillary tubes lie directly on the top side of the plasterboard and thus pass on the heat without much loss. The low weight of an applied mineral wool insulation reinforces this effect.

Ceiling Cooling or Heating In Drywall with quick installation:

Installation of the substructure and a distance about 100 mm need be left between the support profile and the wall connection profile for inserting the capillary tube mats.

The main supply and return lines installation for the capillary tube mats in the ceiling void.

Hook in the retainers or retaining clips between the support profiles.The capillary tube mats are fixed between the support profiles of a suspended drywall ceiling with retaining brackets or retaining clips.

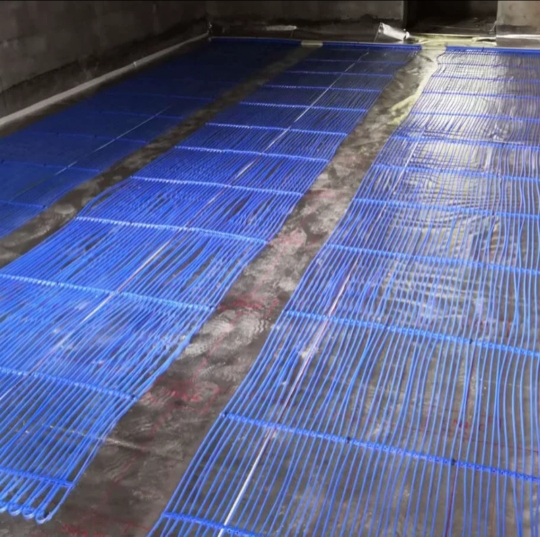

RADIANT UNDERFLOOR HEATING

Greata RADIANT UNDERFLOOR HEATING

Underfloor heating system with capillary tube mats is widely used and acceptable for providing radiant heating in all buildings. It is also ideal for retrofitting underfloor heating and connecting to the existing heating system.

The mats are either integrated into an existing screed or laid directly on an existing floor as a thin-layer underfloor heating system and enable gentle temperature control of floor surfaces.

Due to the large exchange surface and even heat distribution, Greata floor heating can transmit high performances with a lower supply temperature at 28-32℃. This has positive effects on reducing energy consumption, saving costs and protecting our environment.

Capillary tube mat in hostipital

Production Design

During the warm period of the year, the cold ground temperature (+8-12°C constantly) is “transported” to the floor capillary system and the ventilation unit pre-cooler (without the use of a heat pump compressor, only electronic circulation pumps). In this way, the ground circuit, which was cooled during the heating period, is heated during the summer, restoring the balance of thermal energy in nature. The annual SCOP can reach up to 8,9 W/W.

By taking full advantage of energy devices, it is possible to reach a level very close to the characteristics of a self-sufficient, passive house.