How to design main planning principles of the greata system

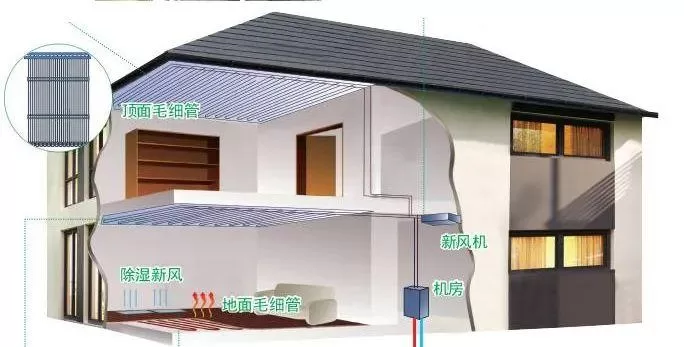

There are many installation methods at the end of the capillary system, including the dry method of integration and the wet method of direct pavement.

- Dry method

The dry method adopts standardized installation, and the capillary is made into a metal plate ceiling or a gypsum board ceiling. The capillary can also be hung on the upper surface of the gypsum board ceiling or adhered to the upper surface of the metal plate ceiling on site. The dry method is more convenient in installation and maintenance, but it is limited by the form of ceiling, with low flexibility and relatively high cost.

- Wet method

The wet method is to directly fix the capillary grid on the top plate, wall or floor with thermal conductive mortar, including laying under the gypsum board ceiling. The wet method has low cost, low floor height occupation, and is more flexible to deal with site conditions. It is applicable to both the air conditioning system of new buildings and the renovation of existing buildings.

Application of capillary net radiation system

Because the capillary network radiation system needs to cooperate with many processes of hardbound construction, it has high requirements for construction level, and the cost of houses with capillary network is much higher than that of ordinary houses. Not many people in the real estate market have mastered and matured the application of this technology, and there is still a lot of room for future development. The following editor has selected several good residential application cases.

Estimate the thermal conductivity of finishing materials

For example, the thermal conductivity coefficient of KNAUF standard plasterboard White GKB 12.5 mm is 0.21 W/(m.K), while that of KNAUF plasterboard Thermoboard is 0.3 W/(m.K) and of Thermoboard Plus – 0.52 W/(m.K).

Capillary tube mats are installed directly under the surface of one or several room enclosing surfaces – either the wall, ceiling or the floor. Therefore, it is important to evaluate the thermal conductivity (W/(mK)) of the finishing materials to ensure the required heating or cooling capacity in the room.

Determining the required capacity

The heating and cooling capacity of capillary mats is not a constant value – it depends on the temperature difference between the average water temperature in the GREATA system and the required room temperature, as well as heat/cold energy transfer in the room is affected by the thermal conductivity of the selected finishing material.When planning the capillary mat system in the ceiling or walls, special attention must be paid to in determining the cooling capacity, as the above-mentioned temperature difference is limited by the occurrence of a dew point, which is controlled by special sensors.

Due to the large capillary mat exchange surfaces, which can exceed 100% of the heated/cooled surface (if we include the active diameter of all capillary tubes), a significant amount of energy can be transferred without draught and noise even with small temperature differences between the active room surface and air temperature in the room.

Surface heat exchange using Greata mats is much more efficient compared to conventional pipe systems due to the small gap (10-30 mm) between the capillary tubes and the large surface area of the mat. This ensures optimal energy transfer to the room. Therefore, only a small difference between the water temperature in the system and the room temperature is required.

It should be taken into account while planning that in the case of heating and/or cooling generated by the capillary mat system, a person feels 2-3 degrees higher (or at cooling – lower) temperature than the air temperature in the room

Installation method of capillary mat

For cooling or hearing purposes, it is recommended to install Greata capillary mats either in the ceiling (adopt various finishing materials). floor cooling is also possible by installing capillary mats in the floor, but a ceiling cooling system is more efficient then floor cooling.

The ceiling surface temperature will be approx. 19°C only at a difference of 2 to 3 K between supply (15°C to 17°C) and reverse (17°C to 19°C). Each control area is equipped with one or more dew point sensors to safely monitor and prevent the risk of condensation. The dew point must be carefully monitored for all surface cooling systems. While the sensor detects condensate, the flow through the mats is stopped either by closing the control valve or by gradually increasing the supply temperature.

This is rare in practice because radiant cooled ceilings are often combined with support ventilation to cope with potential cooling loads.Ventilation is also required to provide fresh air to all users.The relative humidity here is controlled by ventilation and kept within the user-friendly non-critical dew point range – approximately 50-55% relative humidity.Use radiant cooling ceilings to remove reasonable cooling loads.As a result, the air exchange rate can be reduced to the minimum of hygienic requirements (approximately 0.3 to 2 times per hour, depending on the type of building) and reduce the size of ventilation equipment and energy costs.

“Capillary end system construction process”

The basic process is keel – thermal insulation – reflective film – gypsum board – capillary tube mat – plastering – decoration