Technical data for Greata CAPILLARY TUBE MAT

Technical data for CAPILLARY TUBE MAT

| MAT DESIGNATION | GT 10 | GT 20 | GT 20 |

| MATERIAL/COLOUR | Polypropylene (PP-R) recyclable/blue | Polypropylene (PP-R) recyclable/blue | Polypropylene (PP-R) recyclable/blue |

| MAT DISTRIBURTOR PIPE | 20 x 2,0 mm, round | 20 x 2,0 mm, round | 20 x 2,0 mm, round |

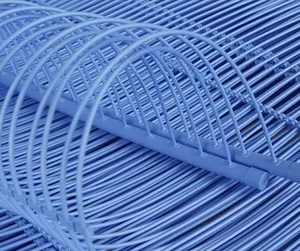

| CAPILLARY TUBE MAT | 4,3 x 0,8 mm | 4,3 x 0,8 mm | 4,3 x 0,8 mm |

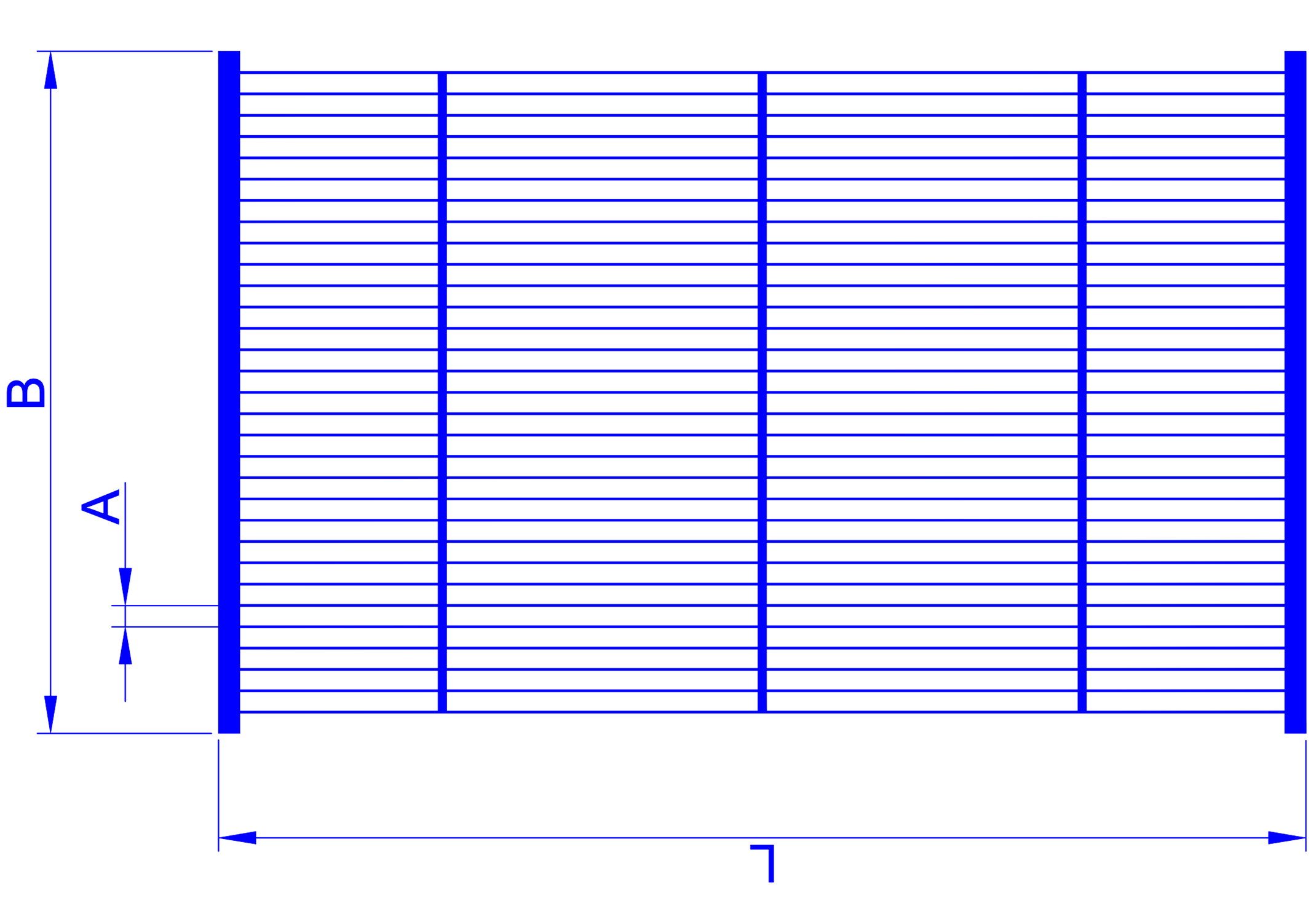

| DISTANCE A | 10 mm | 20 mm | 20 mm |

| LENGTH L | 600 ‐ 6000 mm in 10 mm steps | 600 ‐ 6000 mm in 10 mm steps | 600 ‐ 6000 mm in 10 mm steps |

| WIDTH B | as from 150 mm in 20 mm steps | as from 150 mm in 20 mm steps | as from 150 mm in 20 mm steps |

| CONNECTION TYPE | with open mat distributor pipes/with 2 push-lock connections 10 mm or 15 mm | with open mat distributor pipes/with 2 push-lock connections 10 mm or 15 mm | with open mat distributor pipes/with 2 push-lock connections 10 mm or 15 mm |

| SPEC. WEIGHT | approx. 870 g/m² capillary tube Mat surface | approx. 430 g/m² capillary tube mat surface | approx. 430 g/m² capillary tube mat surface |

| SPEC. VOLUME OF WATER | 0,570 l/m² capillary tube mat surface | 0,320 l/m² capillary tube mat surface | 0,320 l/m² capillary tube mat surface |

| SPEC. TOTAL WEIGHT | approx. 1440 g/m² capillary tube mat surface | approx. 750 g/m² capillary tube mat surface | approx. 750 g/m² capillary tube mat surface |

| PRESSURE STAGE | PN 10 | PN 10 | PN 10 |

| MAX. RECOMMENDED OPERATING PRESSURE | 4 bar | 4 bar | 4 bar |

| MAX. ALLOWED HEATING TEMPERATURE | 60 °C | 60 °C | 60 °C |

| FIELD OF APPLICATION |

|

|

|

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

Description

Technical data for Greata capillary tub mat

| MAT DESIGNATION | SB 10 | SB 20 | GB 20 |

| MATERIAL/COLOUR | Polypropylene (PP-R) recyclable/blue | Polypropylene (PP-R) recyclable/blue | Polypropylene (PP-R) recyclable/blue |

| MAT DISTRIBURTOR PIPE | 20 x 2,0 mm, round | 20 x 2,0 mm, round | 20 x 2,0 mm, round |

| Capillary tube mat | 4,3 x 0,8 mm | 4,3 x 0,8 mm | 4,3 x 0,8 mm |

| DISTANCE A | 10 mm | 20 mm | 20 mm |

| LENGTH L | 600 ‐ 6000 mm in 10 mm steps | 600 ‐ 6000 mm in 10 mm steps | 600 ‐ 6000 mm in 10 mm steps |

| WIDTH B | as from 150 mm in 20 mm steps | as from 150 mm in 20 mm steps | as from 150 mm in 20 mm steps |

| CONNECTION TYPE | with open mat distributor pipes/with 2 push-lock connections 10 mm or 15 mm | with open mat distributor pipes/with 2 push-lock connections 10 mm or 15 mm | with open mat distributor pipes/with 2 push-lock connections 10 mm or 15 mm |

| SPEC. WEIGHT | approx. 870 g/m² capillary tube Mat surface | approx. 430 g/m² capillary tube mat surface | approx. 430 g/m² capillary tube mat surface |

| SPEC. VOLUME OF WATER | 0,570 l/m² capillary tube mat surface | 0,320 l/m² capillary tube mat surface | 0,320 l/m² capillary tube mat surface |

| SPEC. TOTAL WEIGHT | approx. 1440 g/m² capillary tube mat surface | approx. 750 g/m² capillary tube mat surface | approx. 750 g/m² capillary tube mat surface |

| PRESSURE STAGE | PN 10 | PN 10 | PN 10 |

| MAX. RECOMMENDED OPERATING PRESSURE | 4 bar | 4 bar | 4 bar |

| MAX. ALLOWED HEATING TEMPERATURE | 60 °C | 60 °C | 60 °C |

| FIELD OF APPLICATION |

|

|

|

A capillary tube mat, also referred to as a capillary mat, is a specialized fabric made of synthetic or natural fibers designed specifically for plant irrigation. The mat is created by weaving thin capillary tubes into the fabric, which can absorb and distribute water evenly across the surface of the mat.

Capillary tube mats work by utilizing the natural capillary action of water, which occurs when some materials act as wicks and draw water upwards against gravity. In the case of capillary mats, the fibers of the mat act as wicks that draw water up from a reservoir below the mat, transporting it to the plant roots.

These capillary tube mats are commonly used in hydroponic gardening systems, greenhouses, and nurseries to ensure consistent moisture levels for plants. They are also used in commercial agriculture to reduce water usage and improve crop yields.

Capillary tube mats offer several benefits to gardeners and farmers, including reduced water waste, improved plant growth, and decreased labor time. They are typically reusable and long-lasting, making them a cost-effective solution for irrigation needs.