CE approved Greata capillary tube mat

Technical Data:

| Material | Type 3 polypropylene random copolymer, DIN 8078 |

| Collector pipe Ø | 20 x 2 mm |

| Collector tube Ø | 3.5 × 0.5 mm |

| Capillary tube spacing (A) | 10 mm |

| Lenght (L) | 750 – 6,000 mm (in 10 mm increments) |

| Width(B) | 170 – 1,200 mm (in 10 mm increments) |

| Mass when filled | 824 g/m² (without collector) |

| Exchange surface | 1.067 m²/m² |

| Water content | 0.39 l/ m² |

| Cooling capacity* | 83 W/m² |

| Permissible heating water temperature | 60°C |

| Operating pressure | 4 bar |

| Connection for butt and socket welds | 00 (without connections) |

| Field of application | Metal acoustic ceiling systems |

*Capacity achieved under defined conditions

Capillary tube mat is a type of irrigation system used to water plants.

It consists of a thin tube made of a porous material (such as clay or textile fibers) that is placed in the soil.

The tube is connected to a water source (such as a reservoir or faucet) and water is slowly drawn up through the tube by capillary action.

The water is then distributed to the plants through the porous material, providing a slow and steady supply of water to the roots.

This system is efficient as it minimizes water waste and ensures that plants are not over- or under-watered.

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

Description

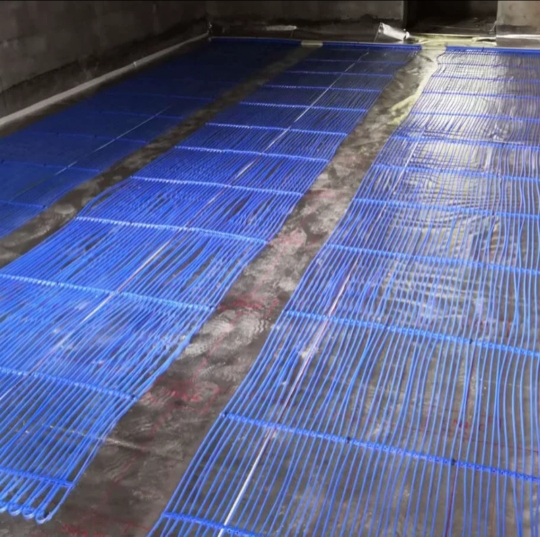

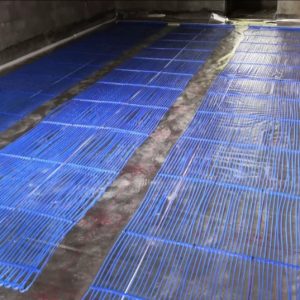

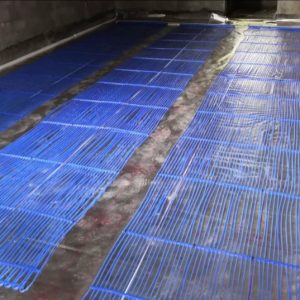

CE approved Greata capillary tube mat used for Cooling and heating with one system

In most buildings, the heat requirement to be covered is so low due to the well-insulated building envelope that greata capillary tube mats invisibly integrated into the metal ceiling not only provide excellent cooling in summer, but can also heat very comfortably and energy-efficiently in the cold season.

High performance

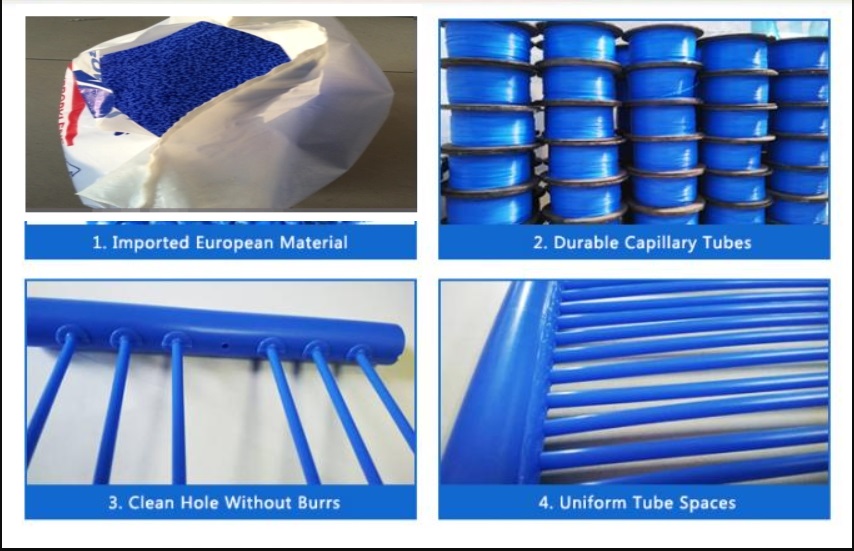

The specially developed capillary tube mat with an oval mat distributor pipe results in an increased contact surface.

Good acoustics

This ceiling design enables optimised room acoustics, as the acoustic values of the perforated metal tiles/panels remain unchanged.

Maximum degree of activation

The dimensions of the capillary tube mat are individually adapted to the size of the tile/panel.

Easy retrofitting

Can be integrated into an existing grid ceiling with metal tiles/metal panels. The hydraulic connection is located in the ceiling void.

Simple combination of active and inactive tiles/panels of the same dimensions is possible. The grid ceiling is reversible.

Quick and easy installation by profressional person

The hydraulic connection is made using a proven push-lock system.

The metal tiles/panels can be installed by the drywall works.

Individual room control

The temperature can be regulated room-by-room.

CE approved Greata capillary tube mat Technical Data:

| Material | Type 3 polypropylene random copolymer, DIN 8078 |

| Collector pipe Ø | 20 x 2 mm |

| Collector tube Ø | 3.5 × 0.5 mm |

| Capillary tube spacing (A) | 10 mm |

| Lenght (L) | 750 – 6,000 mm (in 10 mm increments) |

| Width(B) | 170 – 1,200 mm (in 10 mm increments) |

| Mass when filled | 824 g/m² (without collector) |

| Exchange surface | 1.067 m²/m² |

| Water content | 0.39 l/ m² |

| Cooling capacity* | 83 W/m² |

| Permissible heating water temperature | 60°C |

| Operating pressure | 4 bar |

| Connection for butt and socket welds | 00 (without connections) |

| Field of application | Metal acoustic ceiling systems |

*Capacity achieved under defined conditions