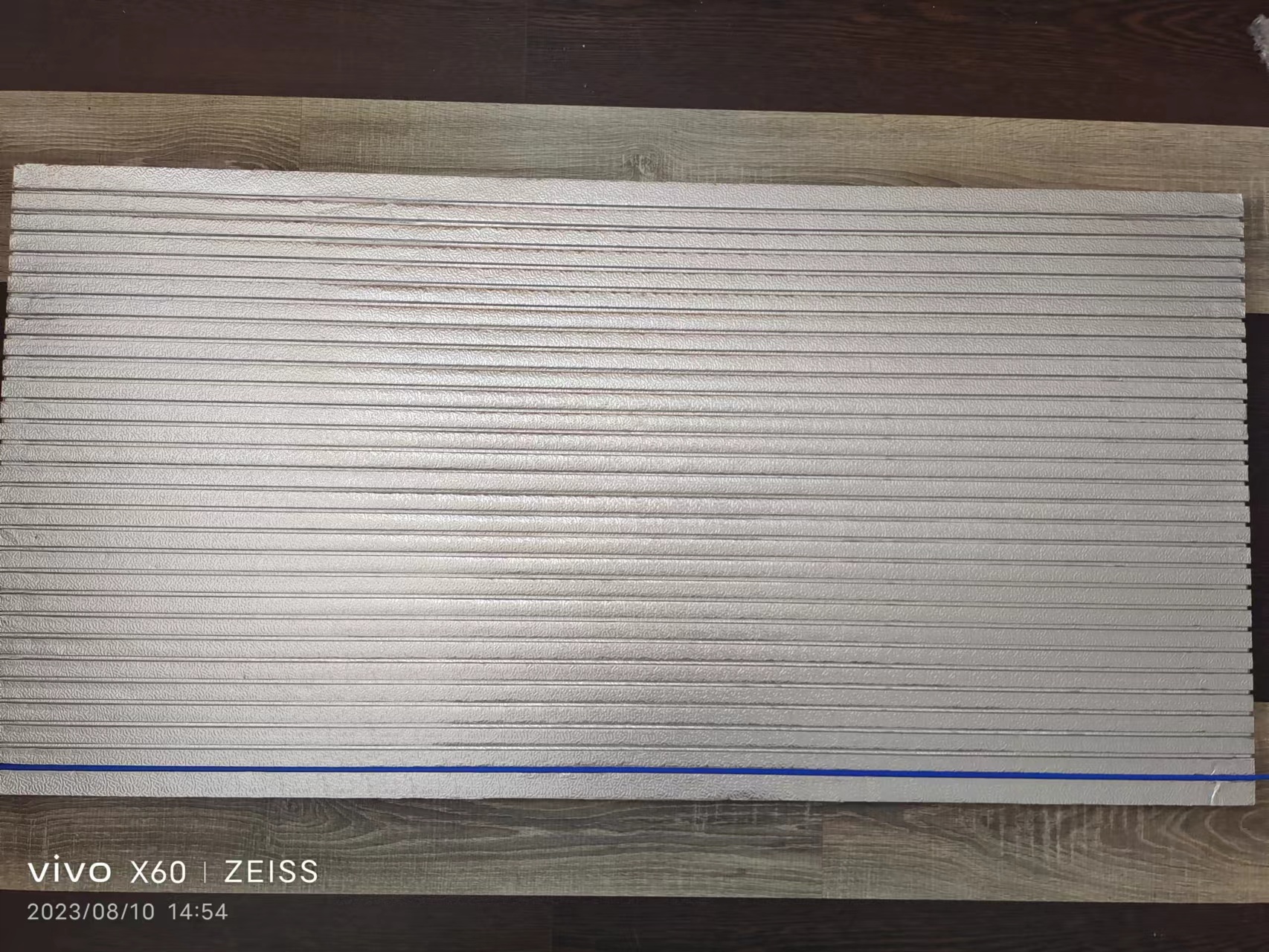

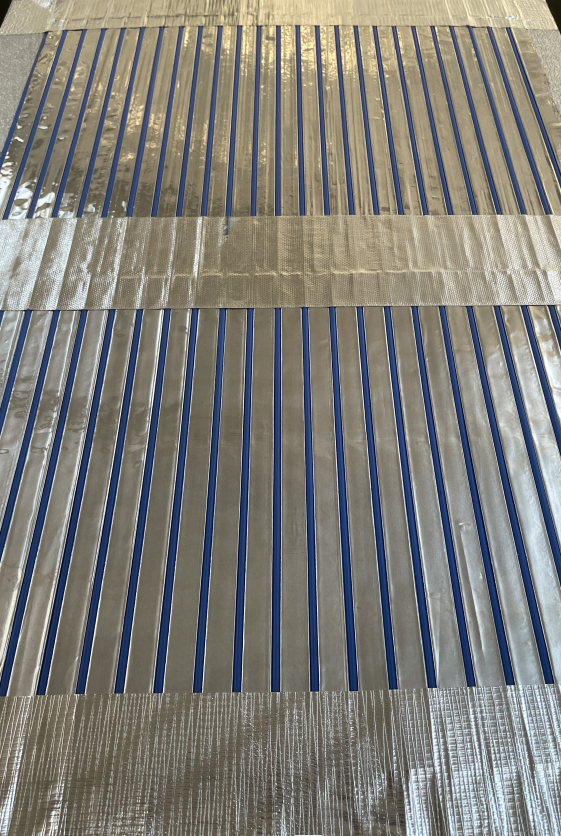

XPS board with 0.2 mm plain aluminum embedded in shaped grooves with capillary tube mat

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

Description

XPS board with 0.2 mm plain aluminum embedded in shaped grooves with capillary tube mat.

What are the features of XPS foam boards?

- Completely closed cell structure

- High resistance to moisture and water absorption

- Low thermal conductivity

- Excellent compressive strength

- Excellent shock absorption

- Dimensionally stable

- Fire Retardant (by adding flame retardants)

- recyclable for scrap and foam board

- Lightweight and durable

- Easy to cut, handle, and install

Other attributes

Requirements for raw materials

- GPPS (virgin or recycled)

- Color masterbatch

- Flame retardant

- Nucleating agent (talc, etc.)

- Blowing agent (CO2, etc.)

The basic recipe for XPS

| S/N | Ingredients | Specification | Percentage |

|---|---|---|---|

| 1 | PS pellets (Virgin or recycled) | MFI between 3-15 are preferable | 90-95% |

| 2 | CO2 | Industry use, purity 99% | 0-4% |

| 3 | Ethanol | Industry use, purity 99% | 0-4% |

| 4 | DME/Butane | ISObutane | 0-4% |

| 5 | Master batch | Carrier: GPPS is preferable | 0-1% |

| 6 | Nucleation agent | Talc finer than 1000 meshes | 0-5% |

| 7 | Flame retardant | 0-5% |

The dosage of each material varies from different product categories.

Options for the blowing agents

- CO2

- Ethanol

- Butane

- Propane

- DME

- HFC

- HFO

The utility of blowing agents is dependent on local availability, cost, and technical requirements. We are more than happy to provide know-how transfer service.

What are the applications of XPS foam boards?

XPS foam boards are the ideal heat insulation materials in “green” buildings. They can also meet the demands of high-performance insulation in different civil engineering branches, industrial floors (cold stores, chilled storage facilities, etc.), and withstanding heavy loads.

General applications

- Thermal insulation of basements

- Thermal insulation of foundations

- Thermal insulation of floors

- Thermal insulation of walls

- Thermal insulation of roofs

- Thermal insulation of utilities and in pools

- Parking decks

- Cold storage floors

- And more…

Extended applications

– Graphite XPS

Graphite is added along with other raw materials to produce graphite XPS foam boards, whose conductivity factor is less prominent than conventional XPS foam boards.

Step1: Feeding System and Main Extrusion System

Step2: Calibration

Step3: Conveyor and Printing

Step4: Cut-off and Rotary Cooling Tower

Step5: Ends Ship-lap Edge Trimming

Step6: Cross-over

Step7: Sides Ship-lap Edge Trimming

Step8: Stacker

Step9: Packaging

Step10: Transport

Where to Buy XPS Foam Boards

If you want to buy a large amount of XPS foam board, you can directly contact us.

We understand both the equipment and the production process, and can provide you with high-quality XPS boards in various specifications.

XPS Boards Specifications We Can Provide:

- Density range: 26~100kg/m3

- Compressive Strength: 150~1500kpa

- Thermal conductivity range: 0.024-0.038W/(m·K)

- Thickness range: 10~200mm

- Width range: 600/900/1200mm

- Length: tailor-made