A New Type of Capillary Tube mat Its Manufacturing Process

Free sample

- Satisfaction guarantee

- money-back guarantee

- Safe payment

- lower customzied cost

- ISO9001-2007

Description

A New Type of Capillary Tube mat Its Manufacturing Process

A new type of capillary tube mat refers to a new design and construction of a capillary tube mat that exhibits improved performance compared to traditional capillary tube mats. Capillary tube mats are typically used for heat transfer and thermal management applications, such as in heating, ventilation, and air conditioning (HVAC) systems.

The manufacturing process of this new type of capillary tube mat involves several steps:

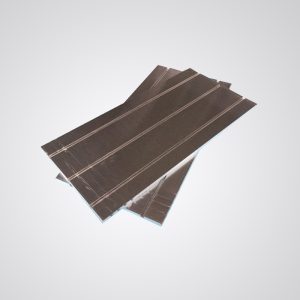

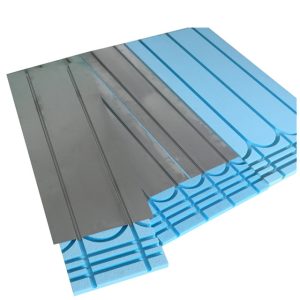

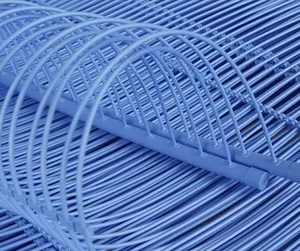

1. Material selection: Different materials can be considered for the capillary tube mat, such as ppr (e.g., PP or PPR), polymers, or composite materials. The choice of material depends on the specific application requirements, including thermal conductivity, flexibility, durability, and cost.

2. Tube formation: The capillary tubes are formed by either extrusion or rolling processes, depending on the selected material. Extrusion involves forcing the material through a die to produce tubes of desired dimensions. Rolling, on the other hand, involves passing a flat sheet of material through a series of rollers to form tubes.

3. Tube sizing: The capillary tubes are then sized to achieve the desired diameter and length. This can be done by cutting the tubes to the required length or by using sizing dies to control the tube dimensions during the manufacturing process.

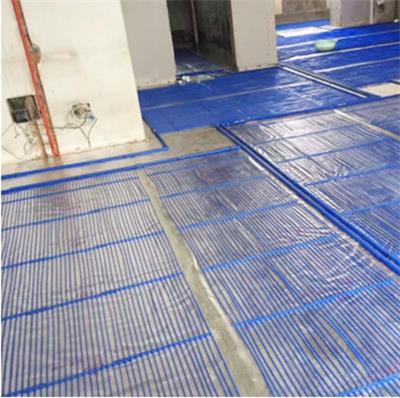

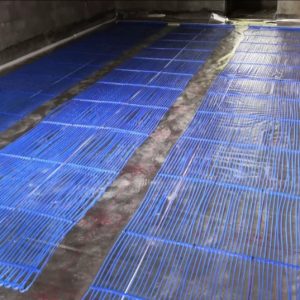

4. Tube arrangement: The capillary tubes are arranged in a specific pattern to create the capillary tube mat. The pattern can vary depending on the desired heat transfer characteristics and overall design requirements. Various arrangements, such as parallel, helical, or serpentine, can be used.

5. Bonding: The tubes are securely bonded together to form the capillary tube mat. This can be achieved through various methods, including adhesives, welding, or mechanical interlocking. The bonding process ensures that the tubes maintain their arrangement and structural integrity during use.

6. Quality control: The manufactured capillary tube mat undergoes rigorous quality control checks to ensure that it meets the required specifications and performance standards. This can involve inspections for dimensional accuracy, tube integrity, and overall mat functionality.

By developing a new type of capillary tube mat and optimizing the manufacturing process, it is possible to enhance the performance, durability, and cost-effectiveness of these products. The new design may incorporate features such as improved heat transfer efficiency, increased flexibility, reduced pressure drop, or enhanced resistance to corrosion and degradation. Additionally, advancements in materials and manufacturing techniques can allow for customization of the capillary tube mat to suit specific applications and operating conditions.

FAQ for More Details:

1. What is the capillary tube mat?

Capillary tube mats are used mainly in radiation systems like cooling & heating ceilings in property construction, convective cooling shafts and cooler columns, as flooring and wall systems for heating and cooling in living houses(primarily single-family homes) as well as ground collectors in conjunction with heat pumps.

2. What are the application areas of capillary tube mat?

The capillary tube system is the solution of choice everywhere where the issue is about providing the user with an optimal, i.e. agreeable, room climate that is beneficial to health. Architectonic issues (space requirement, flexibility, non-visible technology) as well as cost issues also frequently play a decisive role.

3. What are the advatages of capillary tube mat compared with the traditional heating or cooling system?

Compared with the traditional heating and cooling system, capillary tube mat is a kind of more efficient, more

energy-saving, more environmentally friendly, healthy and comfortable and have a longer using life products.

4. Can capillary tube mat be used with heat pump?

Yes. The capillary tube mat can be used with ground source heat pump, air source heat pump, water source heat pump, solar energy system, gas furnace and central heating and cooling system.

5. Is capillary tube mat system energy-saving?

Yes. In winter, the input water temperature is only 28-32℃, which is much lower than the 45-60℃ of the traditional underfloor heating system. In summer, the input water temperature is only 16-18 ℃ , which is much higher than 5-7 ℃ of the common air conditioners.

6. Is there condensation phenomenon when it’s used for cooling?

When used for cooling, there is dew point sensor equipped. When condensation appears, the system will turn off the switch or raise the temperature steadily. And when the condensation disappears, the system will recover to the normal mode.

7. Is capillary tube mat durable?

All the capillary tube mats have to pass the pressure test before delivery. And its using life is around 50 years under normal operation conditions, so there’s no other maintenance expense.

8. Can silting occur in the capillary tube mat system?

Silting is an after-effect of corrosion in the heating and cooling system. By using only corrosion-resistant materials and by implementing system separation in the capillary tube mat system using a stainless steel heat exchanger, silting is not possible.

9. Is Capillary Tube Mat Sample Available?

Yes,Capillary tube mat samples are available in our company. You can contact us directly for sending samples

Please feel free to contact me for more details such as installation instructions, package size, prices..